Fuel Injection

An awful lot of queries through the forum relate to poor running. Sometimes the symptoms are intermittent running, this is often as a result of dirt/rust in the fuel system (see advice here). This article concentrates on the more general setting up of the system.

The Basics

Most cars of the 70s and earlier use a carburetor, while most modern cars these days use electronic fuel injection. The basic job is the same, though, and that is to add and mix the required amount of fuel and air together. When petrol burns in air, it needs to be in a particular mixture ratio - and according to the chemical reaction, the ideal ratio is 14.7:1 air:fuel. This is known as the stoichiometric ratio.

Now, to accommodate a wide variety of operating conditions, from idling to wide open throttle (WOT) at maximum revs, a petrol engine varies the amount of air it draws in. This is (simplification) a function of the revs and the vacuum in the intake system (MAP - manifold air pressure) which is generated by the engine's intake stroke pulling against a closed or partly closed throttle, and varies between minimum and maximum amounts by around 85 times! The fueling system 'measures' this amount of air drawn in and tries to add the required amount of fuel in a fairly consistent ratio.

Mechanical Fuel Injection - Bosch K-Jetronic

At the heart of the Bosch K-Jetronic system is the metering head, which consists of 2 main sections. The lower section has a flap which measures the airflow. In the Golf GTI, air enters from below and travels upwards, rising the flap with increasing air flow. This pushes a plunger into the upper section, which measures the fuel and distributes it to the injectors. Onwards from here, the injectors 'atomise' the fuel (spray it into a fine mist, which makes its burning much more consistent) and deliver it into the cylinder (via the inlet manifold). They open once a threshold pressure of fuel is exceeded and close again against a spring, once this is reduced. In practice, they 'pulse' and open/close many hundreds of times per second, which means that they can be heard as they do this.

The amount of fuel squirted into the cylinders is a direct function of the amount of lift applied to a valve within the fuel distributor, but also the pressure of the fuel. This is the 'control pressure' and is varied during warm up (and, in later developments which can be adapted to the Mk1, during full throttle/part throttle operation).

Cold Start and Warm up aids

So far we've described the basic operation of the system and touched upon the significance of fuel pressure for mixture control. During (cold) starting and warmup, additional fuel is needed because the engine is cold and a proportion of the fuel condenses in the inlet manifold and other areas and doesn't burn. Also the engine oil is colder so there's more friction.

There's 3 devices which assist cold start and warm up:

************************************************************

*************************************************************

******************************************

***(NEED TO ADD THIS TABLE. NEED TO FIGURE OUT IF THIS CAN BE DONE IN COMCODE SOMEHOW RATHER THEN USING THE EDITOR)***

1 Cold Start Valve (CSV), aka 5th injector, cold start injector

2 (behind inlet manifold) Auxiliary Air Valve (AAV)

3 Throttle body. highlighted is the idle screw (at the back, near the bulkhead)

4 - 7 Injectors for cylinders 1-4 respectively

8 Thermo Time Switch (TTS)

9 Warm Up Regulator (WUR)

10 Metering Head/Fuel Distributor

************************************************************

*************************************************************

*****************************************

Cold Start Valve

This is located on the right hand side of the inlet manifold and it squirts additional fuel into the engine during a cold start. The amount of fuel, is determined by 2 things: how warm is the engine, and 'is the starter turning'. (It only operates while you're trying to start the engine, ie the starter motor is spinning). The thermo time switch is located at the front of the head, in the coolant flange. This device determines if the engine is cold enough to require extra fuel, and if so, how long at maximum to fire the 5th injector for. The 5th injector itself, is a simple electrical fuel injector like you'd find in a modern car.

Auxiliary Air Valve

This is a valve which provides an extra amount of air which diverts around the throttle, this raising the idle speed. Its open when the engine is cold and gradually closes (thanks to a bimetallic strip inside it) as it heats up. Its heated up partly by conduction, being attached to the inlet manifold; and partly by its own electrical heater element inside. (The wiring to it is live all the time the engine is running). Note, this is a fairly basic way to try and control idle speed during warmup, later on VW switched to a more effective way to control it, using an Idle Stabilisation Valve (ISV) which also has an electronic module).

Warm Up Regulator

Remember how important fuel pressure is? This is varied during warm up, to provide gradually less and less fuel until the engine is up to normal operating temperature. Once again its heated up both by heat conduction from the engine block and its own electrical heating element. Note that the WUR is an integral part of the fuelling system, so its impossible to bypass it (your fuel pressures would be all wrong!). (If needs be during troubleshooting, the AAV and CSV can be bypassed/disconnected).

Basic Setting up and Troubleshooting

So, your engine doesn't run properly, or doesn't start or run properly at hot/cold, or idles low or fast or something. Before you try to determine which component(s) are actually broken, lets go over some basic theory and explain the basic adjustments you can make.

Engines misfire (run poorly) for only 3 reasons:

A misfire will sound and feel the same for all 3 cases. So you need to be able to measure stuff to determine which one it is. We aren't going to discuss ignition issues in depth here, but you need to eliminate this from your enquiries first. Basic troubleshooting involves setting the ignition timing correctly, checking the plugs are in good condition, checking that wiring is in good condition and all terminals are secure. So, how do you measure mixture?

Unfortunately, the only reliable way to measure mixture is by using instuments. Yes, there's rough guides such as 'getting a feel' for if its overrich by smelling the exhaust, or looking at spark plugs, but you can't measure it accurately enough to make any more than basic checks. The most common tool for measuring mixture is by using a gas analyser which measures CO. When an engine runs rich, some of the fuel only partly combusts with air and forms CO, instead of CO2. So the % CO gives an indication of how rich/lean the engine is. Another tool for measuring mixture is a lambda probe, this is much faster reacting and can measure mixture much quicker, but is more expensive and you're unlikely to come across this in a DIY setting. You can nip down to Halfords and buy a gas analyser for ?50, but you'd spend near on ?200 on a wideband! This pic illustrates a typical CO analyser, and a wideband lambda probe in a home made tailpipe adapter.

A misfire will sound and feel the same for all 3 cases. So you need to be able to measure stuff to determine which one it is. We aren't going to discuss ignition issues in depth here, but you need to eliminate this from your enquiries first.

Basic troubleshooting involves setting the ignition timing correctly, checking the plugs are in good condition, checking that wiring is in good condition and all terminals are secure. So, how do you measure mixture?

Unfortunately, the only reliable way to measure mixture is by using instruments. Yes, there's rough guides such as 'getting a feel' for if its over rich by smelling the exhaust, or looking at spark plugs, but you can't measure it accurately enough to make any more than basic checks.

The most common tool for measuring mixture is by using a gas analyser which measures CO. When an engine runs rich, some of the fuel only partly combusts with air and forms CO, instead of CO2. So the % CO gives an indication of how rich/lean the engine is. Another tool for measuring mixture is a lambda probe, this is much faster reacting and can measure mixture much quicker, but is more expensive and you're unlikely to come across this in a DIY setting.

You can nip down to Halfords and buy a gas analyser for £50, but you'd spend near on £200 on a wideband!

This pic illustrates a typical CO analyser, and a wideband lambda probe in a home made tailpipe adapter.

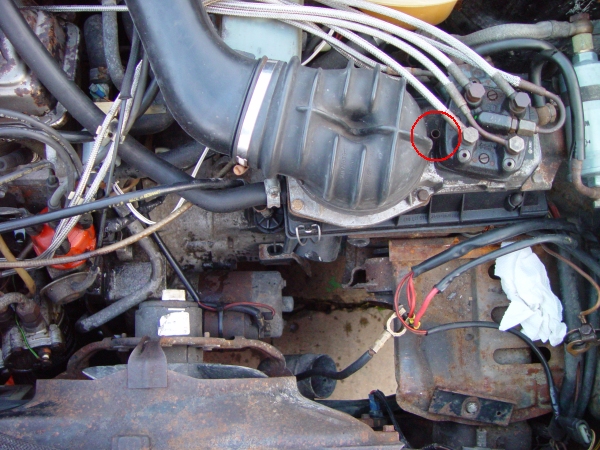

The actual adjustment of mixture is done on a little 3mm hex screw, which is deep within the metering head (see circled area on picture). This is a very sensitive adjustment and small turns have a large influence on the mixture. Clockwise=richer. Also note that you must not rev the engine while its being adjusted (or while the tool is in the screw) and you must only turn the screw, not press it down (the components within the metering head are delicate and can be damaged easily).

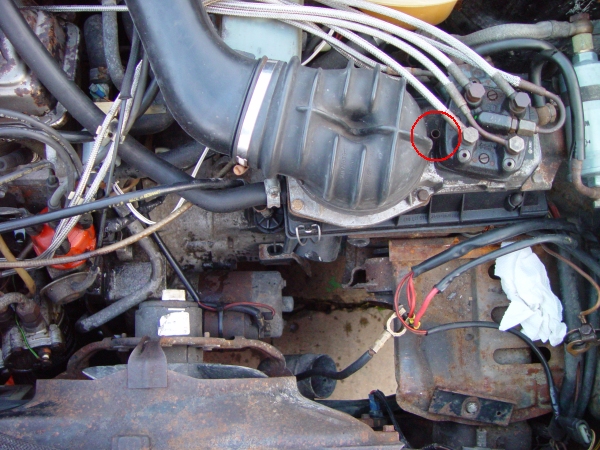

Idle speed is measured sufficiently accurately from the rev counter (all GTIs have a rev counter!) and its adjusted by a 7mm screw on the back of the throttle body, close to the scuttle tray. Indeed its so close its difficult to reach, so you will probably need to use a socket and T-bar. I have a socket with a knurled edge, which is grippy enough to turn by hand once its on the screw. This picture illustrates it, but you don't need to tilt the engine forwards to adjust it!!!

Once you've checked ignition timing, mixture and idle speed, you may well find your engine runs faultlessly - a great number of issues are solved by adjusting the mixture!

The Basics

Most cars of the 70s and earlier use a carburetor, while most modern cars these days use electronic fuel injection. The basic job is the same, though, and that is to add and mix the required amount of fuel and air together. When petrol burns in air, it needs to be in a particular mixture ratio - and according to the chemical reaction, the ideal ratio is 14.7:1 air:fuel. This is known as the stoichiometric ratio.

Now, to accommodate a wide variety of operating conditions, from idling to wide open throttle (WOT) at maximum revs, a petrol engine varies the amount of air it draws in. This is (simplification) a function of the revs and the vacuum in the intake system (MAP - manifold air pressure) which is generated by the engine's intake stroke pulling against a closed or partly closed throttle, and varies between minimum and maximum amounts by around 85 times! The fueling system 'measures' this amount of air drawn in and tries to add the required amount of fuel in a fairly consistent ratio.

Mechanical Fuel Injection - Bosch K-Jetronic

At the heart of the Bosch K-Jetronic system is the metering head, which consists of 2 main sections. The lower section has a flap which measures the airflow. In the Golf GTI, air enters from below and travels upwards, rising the flap with increasing air flow. This pushes a plunger into the upper section, which measures the fuel and distributes it to the injectors. Onwards from here, the injectors 'atomise' the fuel (spray it into a fine mist, which makes its burning much more consistent) and deliver it into the cylinder (via the inlet manifold). They open once a threshold pressure of fuel is exceeded and close again against a spring, once this is reduced. In practice, they 'pulse' and open/close many hundreds of times per second, which means that they can be heard as they do this.

The amount of fuel squirted into the cylinders is a direct function of the amount of lift applied to a valve within the fuel distributor, but also the pressure of the fuel. This is the 'control pressure' and is varied during warm up (and, in later developments which can be adapted to the Mk1, during full throttle/part throttle operation).

Cold Start and Warm up aids

So far we've described the basic operation of the system and touched upon the significance of fuel pressure for mixture control. During (cold) starting and warmup, additional fuel is needed because the engine is cold and a proportion of the fuel condenses in the inlet manifold and other areas and doesn't burn. Also the engine oil is colder so there's more friction.

There's 3 devices which assist cold start and warm up:

- Cold start valve (CSV), AKA 5th injector, cold start injector (and its associated components: the thermo time switch (TTS)

- Auxiliary Air Valve (AAV)

- Warm Up Regulator (WUR)

************************************************************

*************************************************************

******************************************

***(NEED TO ADD THIS TABLE. NEED TO FIGURE OUT IF THIS CAN BE DONE IN COMCODE SOMEHOW RATHER THEN USING THE EDITOR)***

1 Cold Start Valve (CSV), aka 5th injector, cold start injector

2 (behind inlet manifold) Auxiliary Air Valve (AAV)

3 Throttle body. highlighted is the idle screw (at the back, near the bulkhead)

4 - 7 Injectors for cylinders 1-4 respectively

8 Thermo Time Switch (TTS)

9 Warm Up Regulator (WUR)

10 Metering Head/Fuel Distributor

************************************************************

*************************************************************

*****************************************

Cold Start Valve

This is located on the right hand side of the inlet manifold and it squirts additional fuel into the engine during a cold start. The amount of fuel, is determined by 2 things: how warm is the engine, and 'is the starter turning'. (It only operates while you're trying to start the engine, ie the starter motor is spinning). The thermo time switch is located at the front of the head, in the coolant flange. This device determines if the engine is cold enough to require extra fuel, and if so, how long at maximum to fire the 5th injector for. The 5th injector itself, is a simple electrical fuel injector like you'd find in a modern car.

Auxiliary Air Valve

This is a valve which provides an extra amount of air which diverts around the throttle, this raising the idle speed. Its open when the engine is cold and gradually closes (thanks to a bimetallic strip inside it) as it heats up. Its heated up partly by conduction, being attached to the inlet manifold; and partly by its own electrical heater element inside. (The wiring to it is live all the time the engine is running). Note, this is a fairly basic way to try and control idle speed during warmup, later on VW switched to a more effective way to control it, using an Idle Stabilisation Valve (ISV) which also has an electronic module).

Warm Up Regulator

Remember how important fuel pressure is? This is varied during warm up, to provide gradually less and less fuel until the engine is up to normal operating temperature. Once again its heated up both by heat conduction from the engine block and its own electrical heating element. Note that the WUR is an integral part of the fuelling system, so its impossible to bypass it (your fuel pressures would be all wrong!). (If needs be during troubleshooting, the AAV and CSV can be bypassed/disconnected).

Basic Setting up and Troubleshooting

So, your engine doesn't run properly, or doesn't start or run properly at hot/cold, or idles low or fast or something. Before you try to determine which component(s) are actually broken, lets go over some basic theory and explain the basic adjustments you can make.

Engines misfire (run poorly) for only 3 reasons:

A misfire will sound and feel the same for all 3 cases. So you need to be able to measure stuff to determine which one it is. We aren't going to discuss ignition issues in depth here, but you need to eliminate this from your enquiries first. Basic troubleshooting involves setting the ignition timing correctly, checking the plugs are in good condition, checking that wiring is in good condition and all terminals are secure. So, how do you measure mixture?

Unfortunately, the only reliable way to measure mixture is by using instuments. Yes, there's rough guides such as 'getting a feel' for if its overrich by smelling the exhaust, or looking at spark plugs, but you can't measure it accurately enough to make any more than basic checks. The most common tool for measuring mixture is by using a gas analyser which measures CO. When an engine runs rich, some of the fuel only partly combusts with air and forms CO, instead of CO2. So the % CO gives an indication of how rich/lean the engine is. Another tool for measuring mixture is a lambda probe, this is much faster reacting and can measure mixture much quicker, but is more expensive and you're unlikely to come across this in a DIY setting. You can nip down to Halfords and buy a gas analyser for ?50, but you'd spend near on ?200 on a wideband! This pic illustrates a typical CO analyser, and a wideband lambda probe in a home made tailpipe adapter.

- Poor ignition (not discussed here)

- Too rich (too much fuel, outside our ideal stoichiometric ratio)

- Too lean (too little fuel)

A misfire will sound and feel the same for all 3 cases. So you need to be able to measure stuff to determine which one it is. We aren't going to discuss ignition issues in depth here, but you need to eliminate this from your enquiries first.

Basic troubleshooting involves setting the ignition timing correctly, checking the plugs are in good condition, checking that wiring is in good condition and all terminals are secure. So, how do you measure mixture?

Unfortunately, the only reliable way to measure mixture is by using instruments. Yes, there's rough guides such as 'getting a feel' for if its over rich by smelling the exhaust, or looking at spark plugs, but you can't measure it accurately enough to make any more than basic checks.

The most common tool for measuring mixture is by using a gas analyser which measures CO. When an engine runs rich, some of the fuel only partly combusts with air and forms CO, instead of CO2. So the % CO gives an indication of how rich/lean the engine is. Another tool for measuring mixture is a lambda probe, this is much faster reacting and can measure mixture much quicker, but is more expensive and you're unlikely to come across this in a DIY setting.

You can nip down to Halfords and buy a gas analyser for £50, but you'd spend near on £200 on a wideband!

This pic illustrates a typical CO analyser, and a wideband lambda probe in a home made tailpipe adapter.

The actual adjustment of mixture is done on a little 3mm hex screw, which is deep within the metering head (see circled area on picture). This is a very sensitive adjustment and small turns have a large influence on the mixture. Clockwise=richer. Also note that you must not rev the engine while its being adjusted (or while the tool is in the screw) and you must only turn the screw, not press it down (the components within the metering head are delicate and can be damaged easily).

Idle speed is measured sufficiently accurately from the rev counter (all GTIs have a rev counter!) and its adjusted by a 7mm screw on the back of the throttle body, close to the scuttle tray. Indeed its so close its difficult to reach, so you will probably need to use a socket and T-bar. I have a socket with a knurled edge, which is grippy enough to turn by hand once its on the screw. This picture illustrates it, but you don't need to tilt the engine forwards to adjust it!!!

Once you've checked ignition timing, mixture and idle speed, you may well find your engine runs faultlessly - a great number of issues are solved by adjusting the mixture!

There are no pages beneath this page

Submitted by gregski

Hi All, had running problems and needed a pressure gauge hunted high and low then found this

Universal Fuel Injection Gauge Pressure Tester Test Kit Car System Pump Tool Set 788537801863 | eBay

This is lifted straight from ebay cost £40.00 and there is all the right connectors to make a very satisfactory test unit.

Universal Fuel Injection Gauge Pressure Tester Test Kit Car System Pump Tool Set 788537801863 | eBay

This is lifted straight from ebay cost £40.00 and there is all the right connectors to make a very satisfactory test unit.