mk1 Big Turbo vs STI RA V2

Posted

#953749

(In Topic #112530)

Settled In

mk1 Big Turbo vs STI RA V2

Okay the car: mk1 rolling shell from the OC - Mars Red paint was tatty so I decided to re-do it all while I wasn't working:

Ready for a good buffing

Tidying it up completely:

New wings etc:

The Short Runner Inlet Manifold:

Most people opt for either Aluminium or Stainless Steel for an inlet manifold. Both these metals have alloys in them that help stop the metal rusting (corrosion) and also give them a better resistance to heat (thermal resistance). Some people even make them in Mild Steel, however you need to be a bit careful doing this.

Mild Steel hasn't got the aforementioned alloys (or to a lesser degree anyway) and so rusts a lot easier. As you can imagine, especially here in the UK, the cold, wet days can cause condensation on the inside and therefore cause it to rust. Being the 21st century there are probably coatings to prevent that, but thats why most opt for Al or S-Steel (plus the air is travelling at hundreds of ft/sec so I wouldn't want some coating flying in!).

Firstly, when fabricating a decent inlet manifold it is wise to have it set-up for you're specific turbo/engine/rev-limit/targets. The way to do this is pulse timing the incoming air. When an engines intake valve is closed, the air being fed into the port bounces off the back of the valve and back up the tubes. These waves are continuously crashing into each other at hundreds of feet per second. Pulse timing means that the waves flow in harmony, like one big wave, and so are "force fed" into the engine.The key is to have air "pushed" into the intake valve as it opens due to pressure changes.

The way to do this is by changing the sizes of two key area's. Manufacturers, (think it was Jaguar I read, many moons ago), tests show that by altering the Runner (the tubes) lengths and the Plenum (manifold main body) sizes, means that the timing of the waves is changed.

The runners are the main area that changes this but also the plenum can to a lesser degree, too large a plenum, combined with too short a runner means absolutely no low-end. To clarify:

Short runners = top-end/power

Long runners = mid-range/torque

Large plenum = top-end/power

Smaller plenum = mid-range/torque

This is a simplified version, Wiki's is a more technical explanation: http://en.wikipedia.org/wiki/Manifold_(automotive_engineering)

There are a few other things to note too, like the internal diameter of the runners, what Throttle Body you will use and its location (and the throttle cable etc). The size and VE of the engine and more. Don't be put off, just do a little reading first and prepare well.

Back to the fabbing:

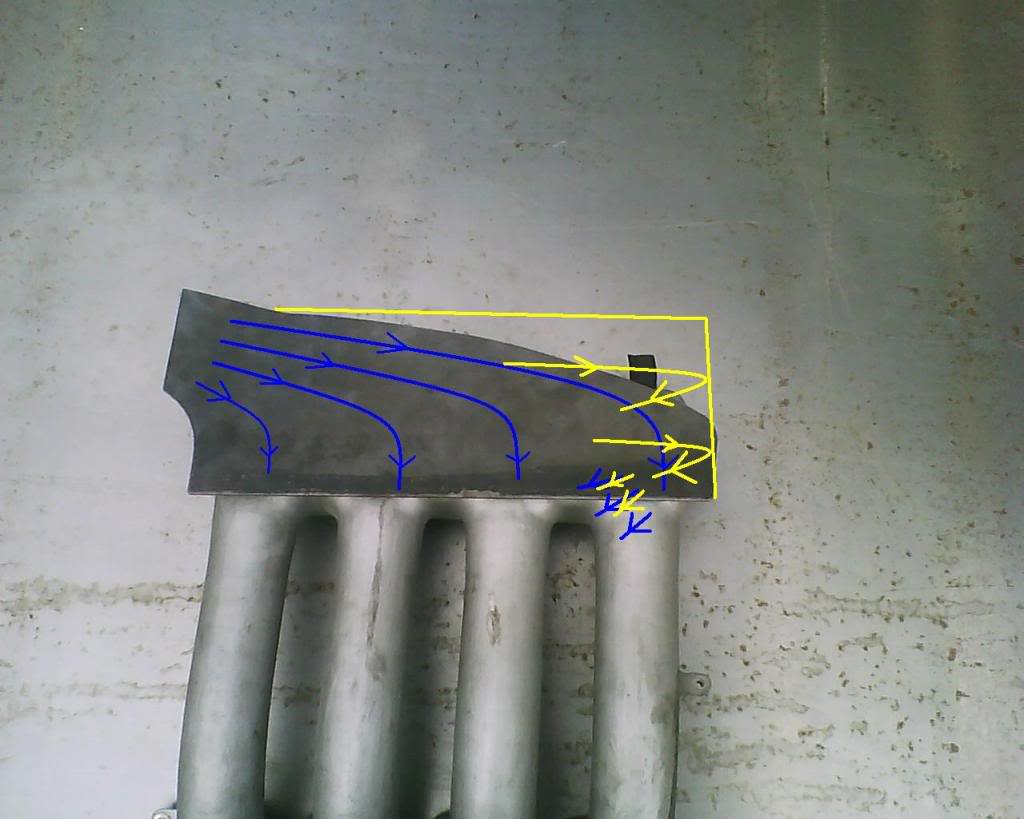

The reason I chose a tapered plenum design is because it helps promote an even air distribution to each cylinder. A large, flat ended plenum can cause problems in the end cylinder as the air crashes of the wall and creates turbulence. The air/fuel mixture is not the same as the other 3. Did a quick pic to show what I mean:

As i'm making more than one I also have to think about several other factors that people may request. The first template I cut out was based heavily on the standard ABF manifold. This manifold has a slight taper to it but also has a lot of basic cast design flaws that you may find on a production vehicle. There are several things to note in the following picture:

The turquoise/green line shows the standard ABF layout, a mix of both tapered, correct use and easy, cast manufacturing, for profit there.

The Blue line shows that I am not happy with the angle of the cut I made and that it may cause problems for the incoming air. This area needs to be smoothed out.

The red line shows that the initial TB side to it would only be good enough for the standard 3" ABF TB. If people wanted to go bigger then it would mean a different manifold for very high hp applications.

The yellow line shows that I cut out this area at an angle for a smoother air flow into the first cylinder. However, as its being made in S-Steel, then to actually curve it to this area would mean extra labour and extra cost, comprises need to be made. (Andwhich is why they're mocked in Mild Steel sheet!).

So plenty to do now! I've a good idea on what i'll be doing but no doubt change a few things along the way. Questions welcome. I'll add plenty of info on things for the novices so people can just copy it and have a go themselves! :twisted:

Posted

Settled In

looking forward to hearing about the scooby gettin whooped!

Posted

Settled In

Posted

Settled In

Posted

Settled In

Posted

Local Hero

diesel crank should be good for plenty of torque, but be wary of its limiting on the revs. it won't really want to rev much past 7500 (if that!)

if you're wanting it to rev high, i'd get the 92.8mm crank back and settle for 1984/2008/2032cc maybe even go for 84mm bore to give 2057cc

but then again, i might have completely the wrong end of the stick

1983 Polo CL - daily

1984 Golf G60 Syncro - sold

1989 Rallye Golf - sold

1992 Corrado G60 - crushed

1989 Polo C - chopped and crushed

1991 309 Style - crushed

1984 Golf G60 Syncro - sold

1989 Rallye Golf - sold

1992 Corrado G60 - crushed

1989 Polo C - chopped and crushed

1991 309 Style - crushed

Posted

Settled In

Posted

Local Hero

sounds cool mate.

i hope you're not running the charger and turbo in series?

1983 Polo CL - daily

1984 Golf G60 Syncro - sold

1989 Rallye Golf - sold

1992 Corrado G60 - crushed

1989 Polo C - chopped and crushed

1991 309 Style - crushed

1984 Golf G60 Syncro - sold

1989 Rallye Golf - sold

1992 Corrado G60 - crushed

1989 Polo C - chopped and crushed

1991 309 Style - crushed

Posted

Settled In

0 guests and 0 members have just viewed this: None.