Mirror Polishing a 1.8T Aluminium Manifold - Guide

Posted

#1193659

(In Topic #142634)

Old Timer

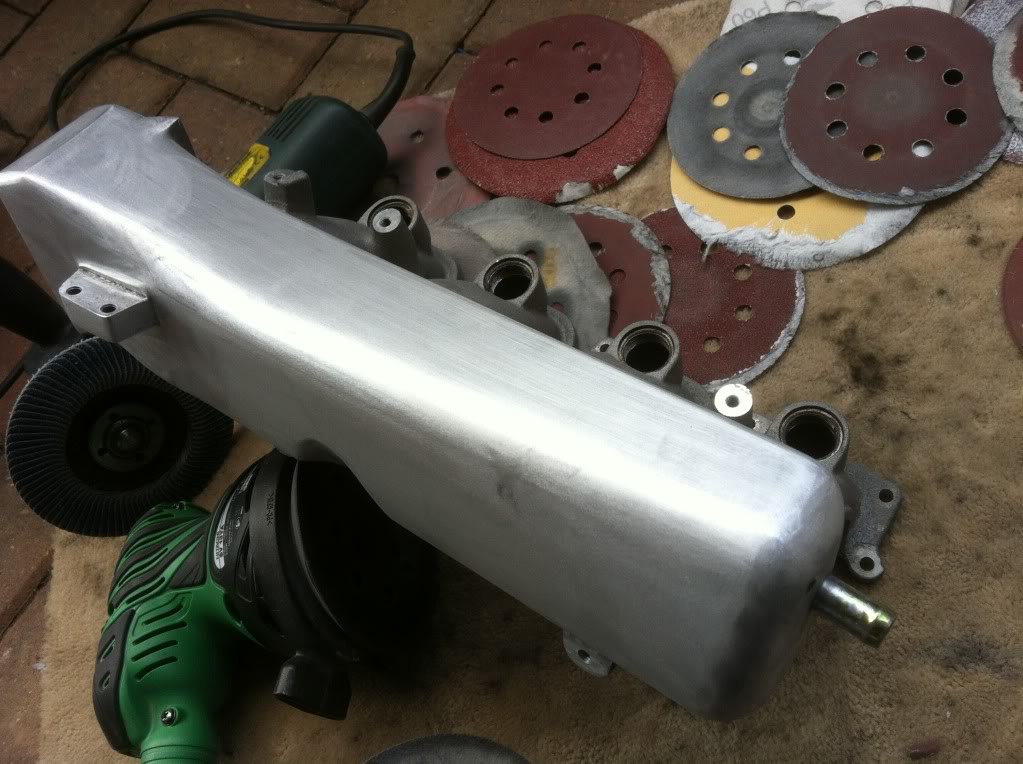

Mirror Polishing a 1.8T Aluminium Manifold - Guide

I always get asked at the shows ( who does your polishing ) so I thought Id help out some of you folks to do it yourself and save hopefully a small fortune in the process.

TOOLS NEEDED

RANDOM ORBITAL SANDER

ANGLE GRINDER WITH FLAP WHEEL 40 OR 80G

POWERFILE ( NOT ALWAYS NEEDED UNLESS YOU HAVE A LOT OF INTRICATE PARTS)

LOADS OF GOOD QUALITY VECRO DISCS

BLUE POLISHING COMPOUND

DRILL OR BENCH GRINDER POLISHER

WHITE SOFT STITCHED POLISHING MOP

GRITS BEST FOR POLISHING ROUGH CAST ( IN ORDER OF USE)

40

80

120

240

320

500

800

1200

1500

At the start standard factory manifold looked like this

Start with the 40g this is probably the most important stage , the aim is to get all the rough cast to a smooth even finish, but be very careful as you can damage the part, if its your first time use a orbital sander as this will do the job more gently but will take longer, if your a dab hand you can use a angle grinder with a flap disc (40g) very lightly to remove all imperfections and even cast joins and seams.

Once done it should look like this

Then its time to hit it with a 80g making sure to take your time and remove all the previous scratches made with the 40g, should look like this

Then just continue stage after stage after 80g move to 120g remembering each time to remove scratches from the previous sandpaper

Finally to the 1500 stage should look like this

If you've got this far then your sanding days are done now its time to polish !

Using your bench polisher or drill with mop apply the blue compound and start polishing

Should look like this after first pass, take your time move slowly and not to much pressure and even.

Once happy then apply less blue compound and start the final buff , doing the whole part again until no scratches are left and you have a mirror polish shine

You can keep it looking like this by once a month polishing by hand with autosol aluminium polish works great ! The process above can be used on wheels and virtually any aluminium part .

Hope this guide helps you guys out !

Posted

Old Timer

Posted

Old Timer

MORE POLISHING !

Warning - Do not even attempt unless you have a lot of time and patience.

Firstly had to get the Bosch Multi and mini grider , dremel and plenty more vecro discs and even 3m rolocs discs out for this next part

Taken the cast down took what felt like ever ! just when you thought you were done Id noticed more cast texture

After about 4 hours got to this stage below

Then after another hour checking all sections were up to a 1500 finish it was finally time for polishing ( AGAIN)

And here we have it a fully polished inlet manifold ! ( still needs little final buffing but looking pretty nice )

Enjoy !

Posted

Old Timer

You can write all the how to guides in the world but you can never write one about how to be patient

Posted

Life Member

Posted

Old Timer

Posted

Old Timer

Posted

Settling In

Posted

Old Timer

polishing

0 guests and 0 members have just viewed this: None.