K-jet masters !! Advice required on rebuild !

Posted

#1545979

(In Topic #206834)

Settled In

16v wur and m/head

After a long spell of fueling issues ive decided to start from scratch and im encountering some issues…

I have stripped and cleaned everything, pumps lines filters metering head ect.

After refitting the metering head I wound out (leaned) the mixture screw with the injector lines off. I then richened it untill fuel began to come out of the injector holes. Fitted the lines again. Whilst doing all of this ive tried to fit the 16v wur. The trouble im having is I cannot get the wur to 3.4 bar as the warm control pressure ? Also when it gets hot the engine begins to struggle at idle and the dies.

The wur is going over 4 bar before the engine is at operating temperature ?

Would richening the mixture screw at the m/head allow the pressure at the wur to drop ?

Also if I refit the standard wur the engine still dies when warm, does this imply that the mixture needs to be richened ?

Just to add that the system pressure is spot on at 5.1 bar !

Sorry about being long winded !! Hope this makes sense to you as it doesn't to me lol.

Thanks, jake.

Posted

Local Hero

Posted

Settled In

Ive watched videos on you tube showing how to set it up and their pressures creep up where as mine starts high in the first place ? Doesn't seem to matter how I adjust the 16v wur, I cant get the pressure down ?

I will have another bash with the standard wur tmw to get her running and then go back to the 16v wur again.

Think I need to go over the k-jet diagrams again lol.

Posted

Local Hero

If they are blocked your pressure will be too high from cold but then it won't rev cleanly from cold.

The WUR is just like a pressure relief valve which increases the control pressure as the engine warms. If it the pressure is high to begin with the fuel pressure may not be having any where to disperse to hense check the gauzes behind the banjo bolts on the WUR.

If your pressure is high when hot then you need to adjust your idle mixture to get it running nice when warm. I would try and get it running nicely when hot and then sort out any cold start issues rather than the other way round. Cold start, although is important is only a temporary situation.

Posted

Local Hero

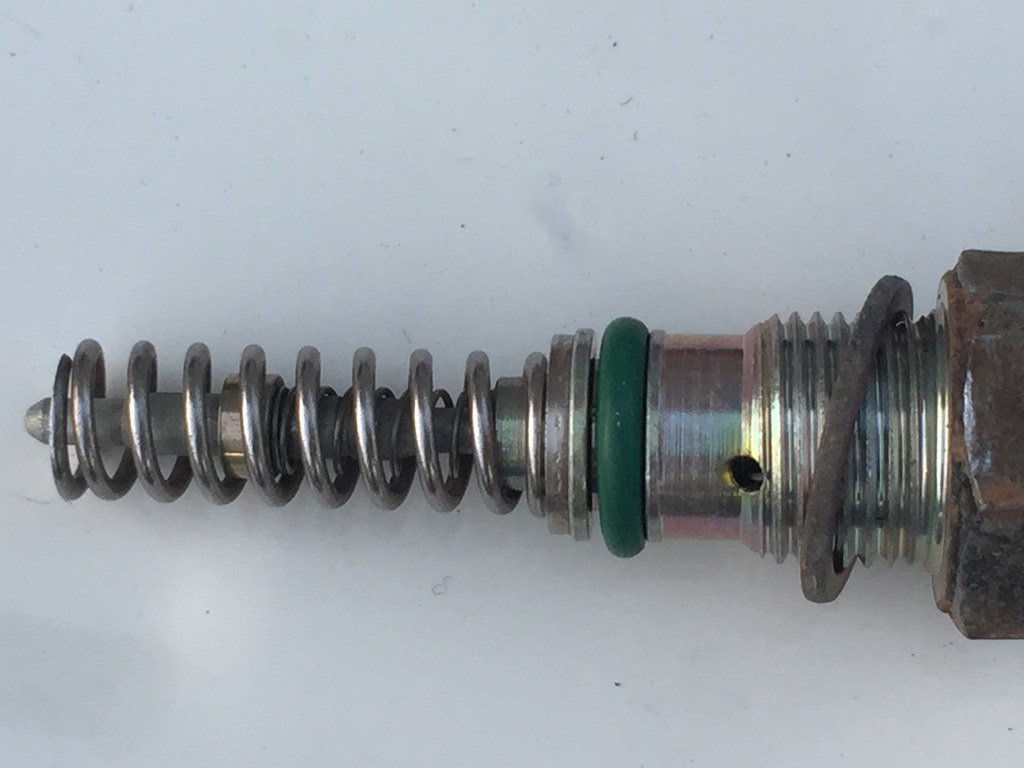

There's also another part of this not in the picture which is at the end of this PPR. check the o'rings have not squared off. This does happen & is not checked often at all!!

Where the green washer holder is & to the left you see a flat washer, sometimes this can wear & you can add smaller shims to add pressure..

Sometimes the WUR can get the smallest bits of debris in the gauze, this is very delicate so care needed as its delicate - try Wynns injection cleaner to spray the gauze. The WUR has an inlet & outlet on with 13 (10nm) & 14mm (20nm) bolts.. the outlet, i believe, goes to the top of the FD. May be an idea to renew the copper washers if you take things apart…

The idle screw is behind the throttle body - 7mm hex head - personally if adjusting i'd wait until the engine was warm.

Last edit: by Deandubya

Last edit: by Deandubya

Posted

Settled In

Ive discovered that the diaphragm on the 16v wur is shot so ive ditched it. Put the old wur on and it was running on tickover. Went to go and check the co levels with a old gunson gas tester but now its hot it wont tick over enough to even get a reading. I can hold the throttle to keep it running but im not quick enough to get to the front of the car to check the tester lol.

Just to add that with the old wur the pressure crept up evenly to about 3.8 bar but then It got hot and wouldn't run. Seem to have trouble when ive switched the car off and try and restart it again. Should have left it ticking over whilst I set up the gas tester…

Posted

Settled In

Seems as though fuel flow is dropping off as it runs for longer ? Keeps making a sound as if its running out of petrol now ? Feel like screaming with this car sometimes lol.

Posted

Settled In

Just wont idle.

Think this is beyond me now and seriously considering selling up as I need something reliable. Mot has already run out and the insurance is due and cant justify throwing more money and time at it…

Posted

Local Hero

If you want to get to the bottom of tuning a K-Jet system properly, fit a wideband lambda and AFR meter. Then learn about what is a "good" air-fuel ratio, at what operating condition - for examle during WOT you really want something like 12.0-13.0; during part throttle cruising then 14.7-15.0 is good, but you could flirt with 15.5 if you wanted to etc for fuel economy. And that some engines, or operating conditions, don't actually benefit greatly from slight enrichening (ie AFR 12 rather than say 14). (I reckon the GTI engine does though - it applies more for modern well-flowing engines). Also, bear in mind there's a relationship between timing and AFR - by running on the "rich" side you can advance the timing a little more.

The easiest way to add an AFR meter is to make a bracket up that allows the lambda probe to sit on the tailpipe, but you won't get decent readings at low/idle speeds. A better way would be to have a bung welded into the manifold or exhaust, at the point around 6-12" after the individual branches have joined. Remember to try mount the probe vertically upwards or at least so it doesn't get condensation flowing onto it.

Also I assume you know about the "WUR mod" - taking a 16V WUR and drilling a hole in the back, to reveal a 'secret' allen key adjuster which can be used to tweak the mixture while under load vs part/idle mixture (the 16V WUR has a vacuum connection to sense load).

And that the "curve" of the fuel ratio is related to the shape of the cone within the metering head, ie its a fixed shape. And that VE of an engine means its flow capability changes at different loads/speeds - so the cone shape is optimised for a particular engine set of internals and a broad ranging driving style, with K-Jet all you can do is shift this around to be optimal at a certain point and still driveable at the bit thats not optimal.

Posted

Settled In

I was having a play again just now double checking that the lift pump ect were still working. Strange thing was that it did idle on its own for a couple of minutes.

I switched off the ignition left it for a minute, went to restart it and it would not idle again.

This is whats driving me crazy !! This morning it idled like a dream. Switched the car off to grab the gas tester and then it wouldn't start properly or idle on its own.

Its like something is only operating as and when it wants ??? I did have problems with the old pump relay, it used to cut the spark as and when it wanted. The new topran one is only a couple of months old ?? Maybe I'll try a new genuine vw fuel pump relay and see how It goes.

Posted

Local Hero

But then you start to mention rusty fuel filler problems…

Posted

Settled In

Recently though ive changed or cleaned everything. Even blown air through all the lines ect. It has a different m/head on now as well as new injectors, pumps and filters.

Its basically a new engine as well.

Fully rebuilt block with lightened and balanced crank,

Big valve tsr style pack d head,

Piper ultimate road cam,

K&n panel filter,

4 branch manifold

New brakes

New suspension

New alternator

Well you get the idea.. thats why its so frustrating for it to be suffering a fuel issue lol.

I think I will try and richen the mixture as ive got nothing to lose. At least I know how to set it back again now.

Posted

Local Hero

An AFR meter will show a non-spark (with an anomolously high O2 reading for a brief moment).

If you suspect the fuel pump relay, you can bypass it temporarily to eliminate it from your enquiries and get it running sweet, then reinstate it (and if problems return, its the relay or its wiring).

Posted

Local Hero

How was the cam timing set up? Has the dizzy advance been altered to suit the different power band?

With the pack d head etc you'll be on the limit to get the most out of it all with the K jet as it has limitations on fuel delivery.

I initially thought we were just dealing with a standard motor!

Posted

Old Timer

Posted

Settled In

Its down to fuel supply or lack of should I say !

I fully leaned out the mixture and got it ticking over at a steady pace. As I richen the mixture the car starts to pick up and then reaches a point where its not getting enough fuel to rev any further.

There is petrol in tank before anyone says it ! Lol.

it strikes me as stange that I can reach 5.1 bar of pressure and yet there be not enough flow.

The pumps are less than a year old so would be quite annoying if they have failed already.

Does anyone know the rate of flow that they should be supplying ? Not pressure but delivery rate ?

I will try removing fuels pipes and run the pumps into a container to see where im at. will also check for and damaged or crushed pipes under the car !

Posted

Settled In

Posted

Settled In

I then measured the flow back into the tank on the return line and it was about the same. Not sure if this is right ?

If it is then im a bit stumped.

Posted

Settled In

Snapping this fitting hasn't help me either haha.

This car is fighting me all the way !

Posted

Settled In

Yomp said

If your running high lift cam etc then you'll probably need to richen the co quite a bit as you'll be losing lots of efficiency at idle and will struggle to get a decent idle with the 280 duration.

How was the cam timing set up? Has the dizzy advance been altered to suit the different power band?

With the pack d head etc you'll be on the limit to get the most out of it all with the K jet as it has limitations on fuel delivery.

I initially thought we were just dealing with a standard motor!

Hi yomp, the thing is that it was running with all this work done before. I had to take the cylinder head off to do something and it was sitting for a couple of weeks..put it all back together and then it decided it wouldn't run ! Thats what's confusing me !!

0 guests and 0 members have just viewed this: None.