AT LAST! Hairys Resto!!

Posted

Website Manager

Posted

Local Hero

Andy

LINCOLNSHIRE REGION - https://www.facebook.com/groups/467122313360002/

1983 MK1 Golf GTI Campaign Model - Under (looooong) resto!

1962 Rover P4 80

2002 BMW 745i

2008 BMW Z4 2.5Si

LINCOLNSHIRE REGION - https://www.facebook.com/groups/467122313360002/

1983 MK1 Golf GTI Campaign Model - Under (looooong) resto!

1962 Rover P4 80

2002 BMW 745i

2008 BMW Z4 2.5Si

Posted

Old Timer

Great work though, coming along nicely

Matt

Posted

Local Hero

So this morning I've been making repair patches for the floor by the front of the arch tub and the inner arch where the fuel lines come through. Just having a spot of lunch then will be welding.

One question in the meantime however. I had a nice big box of parts arrive from VWH this morning - mostly suspension fixings - but also my new (next!

My original one is so rotten so I have no reference - holding the filler pipe against each panel I'm guessing I shouldn't have this flange but would be grateful if someone knows and can confirm

Andy

LINCOLNSHIRE REGION - https://www.facebook.com/groups/467122313360002/

1983 MK1 Golf GTI Campaign Model - Under (looooong) resto!

1962 Rover P4 80

2002 BMW 745i

2008 BMW Z4 2.5Si

LINCOLNSHIRE REGION - https://www.facebook.com/groups/467122313360002/

1983 MK1 Golf GTI Campaign Model - Under (looooong) resto!

1962 Rover P4 80

2002 BMW 745i

2008 BMW Z4 2.5Si

Posted

Old Timer

Last edit: by zorg

Last edit: by zorg

i pressed the little red button

Posted

Local Hero

zorg said

mine looks like the silver one, maybe not as deep though..

Ah ok, cheers for that

Andy

LINCOLNSHIRE REGION - https://www.facebook.com/groups/467122313360002/

1983 MK1 Golf GTI Campaign Model - Under (looooong) resto!

1962 Rover P4 80

2002 BMW 745i

2008 BMW Z4 2.5Si

LINCOLNSHIRE REGION - https://www.facebook.com/groups/467122313360002/

1983 MK1 Golf GTI Campaign Model - Under (looooong) resto!

1962 Rover P4 80

2002 BMW 745i

2008 BMW Z4 2.5Si

Posted

Local Hero

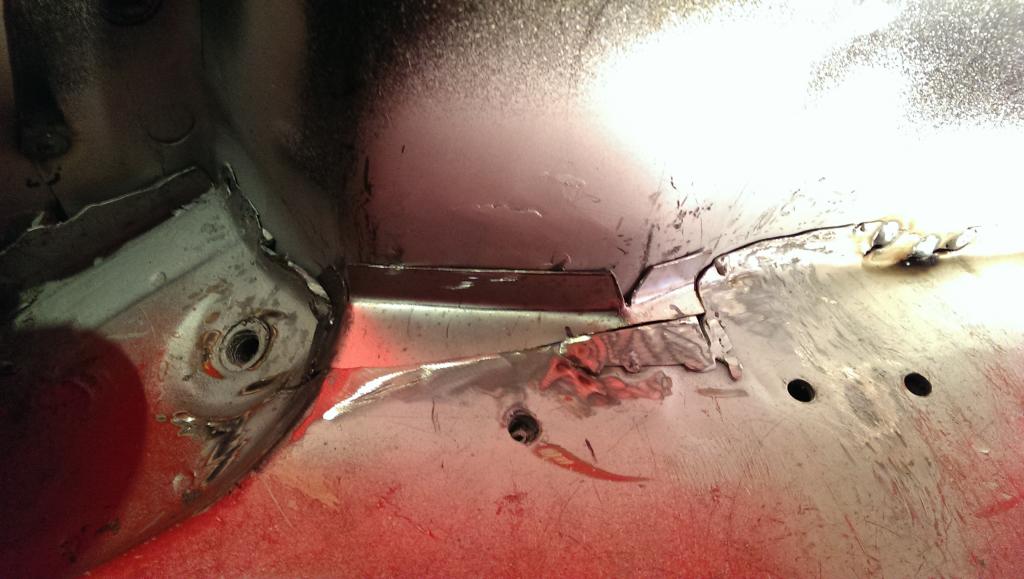

…then used the section cut out the arch tub to fill in under where the fuel pipes come through;

…and then welded in a filler strip to close the gap;

Still a little bit to finish off and tidy up but the tub itself is fully welded in now so I'm happy

Andy

LINCOLNSHIRE REGION - https://www.facebook.com/groups/467122313360002/

1983 MK1 Golf GTI Campaign Model - Under (looooong) resto!

1962 Rover P4 80

2002 BMW 745i

2008 BMW Z4 2.5Si

LINCOLNSHIRE REGION - https://www.facebook.com/groups/467122313360002/

1983 MK1 Golf GTI Campaign Model - Under (looooong) resto!

1962 Rover P4 80

2002 BMW 745i

2008 BMW Z4 2.5Si

Posted

Moderator

What's next on the list?

Posted

Local Hero

I need to finish patching the floor - that's doing my head in as keep blowing holes!!

The OS sill and bottom of B-post will take a bit of work too I think but once this rear corner is done it's the bulk of the welding work I think - although there'll still be plenty left!

Not sure I'll get in the garage today as the bottom of my drive is flooded. Oh well, I'm still on track to get it done on time, although it's early days!

Andy

LINCOLNSHIRE REGION - https://www.facebook.com/groups/467122313360002/

1983 MK1 Golf GTI Campaign Model - Under (looooong) resto!

1962 Rover P4 80

2002 BMW 745i

2008 BMW Z4 2.5Si

LINCOLNSHIRE REGION - https://www.facebook.com/groups/467122313360002/

1983 MK1 Golf GTI Campaign Model - Under (looooong) resto!

1962 Rover P4 80

2002 BMW 745i

2008 BMW Z4 2.5Si

Posted

Moderator

Posted

Local Hero

The big test will be when it's back on wheels again, my fat ass could level it up though!

Andy

LINCOLNSHIRE REGION - https://www.facebook.com/groups/467122313360002/

1983 MK1 Golf GTI Campaign Model - Under (looooong) resto!

1962 Rover P4 80

2002 BMW 745i

2008 BMW Z4 2.5Si

LINCOLNSHIRE REGION - https://www.facebook.com/groups/467122313360002/

1983 MK1 Golf GTI Campaign Model - Under (looooong) resto!

1962 Rover P4 80

2002 BMW 745i

2008 BMW Z4 2.5Si

Posted

Old Timer

Posted

Local Hero

Andy

LINCOLNSHIRE REGION - https://www.facebook.com/groups/467122313360002/

1983 MK1 Golf GTI Campaign Model - Under (looooong) resto!

1962 Rover P4 80

2002 BMW 745i

2008 BMW Z4 2.5Si

LINCOLNSHIRE REGION - https://www.facebook.com/groups/467122313360002/

1983 MK1 Golf GTI Campaign Model - Under (looooong) resto!

1962 Rover P4 80

2002 BMW 745i

2008 BMW Z4 2.5Si

Posted

Marketing Manager

1973 BMW 3.0CS "Helga"

1981 VW Golf GTi "Agolf"

1986 Ford Escort RS Turbo S2

1987 BMW M535i - 'Klaus'

Instagram: @ahmet_e9

Posted

Settling In

Hairyarse said

With some gentle pressure applied by him with his feet on the inside of the tub, I was able to put about 6 or so of the welds in to hold the tub in place enough for me to finish it off.

I assume this was so the panels clamped together enough to plug. Another way to clamp the panels together if you've not got a helper is to drill very small holes through both panels adjacent to your plugs and use some self tapping screws. As the screws go through they clamp the two layers of metal together. Just don't screw too far as it's the taper on the screw that helps pull the panels/flanges together at different rates so they clamp.

Give it a go, it pinches panels together really nicely. Fill the holes with weld after and you'd never know they'd been there.

Excellent work btw. I've just found exactly the same rot in mine as you have in yours and seeing how you've gone about it will help no end.

Posted

Local Hero

This one was an issue as at least 20mm gap before putting any pressure on - and needed a fair bit.

I think most MK1's rot a lot on this rear corner as there's so many items on this side in the fuel system for mud and crud to get trapped on - it's the bulk of the body work I need to do I think.

Good luck with yours

Thanks again for the tip

Andy

Andy

LINCOLNSHIRE REGION - https://www.facebook.com/groups/467122313360002/

1983 MK1 Golf GTI Campaign Model - Under (looooong) resto!

1962 Rover P4 80

2002 BMW 745i

2008 BMW Z4 2.5Si

LINCOLNSHIRE REGION - https://www.facebook.com/groups/467122313360002/

1983 MK1 Golf GTI Campaign Model - Under (looooong) resto!

1962 Rover P4 80

2002 BMW 745i

2008 BMW Z4 2.5Si

Posted

Local Hero

…….if you had a diesel there would be non of that melarkie lol

Bert

Posted

Local Hero

Andy

LINCOLNSHIRE REGION - https://www.facebook.com/groups/467122313360002/

1983 MK1 Golf GTI Campaign Model - Under (looooong) resto!

1962 Rover P4 80

2002 BMW 745i

2008 BMW Z4 2.5Si

LINCOLNSHIRE REGION - https://www.facebook.com/groups/467122313360002/

1983 MK1 Golf GTI Campaign Model - Under (looooong) resto!

1962 Rover P4 80

2002 BMW 745i

2008 BMW Z4 2.5Si

Posted

Local Hero

So yesterday….

Had to fab another small panel to patch in the lower corner of the arch tub as it doesn't follow the line of the chassis rail. Almost ready to weld…

All done. I couldn't get good access to grind all the welds back due to the contours of the tub. However, it will be seem sealed and stone chipped so wont be seen…

All zinc primed in the bare areas and jobs a good-un. I'm really quite pleased with it actually!

So on to today;

I started off on the OSR chassis leg. When I was patching up the boot floor I was conscious that the patches may conflict with the chassis leg flange but thought I'd get around it no problem. However, it was so uneven I was really struggling. In the end I've had to cut a big hole out of my floor where the flange goes so it will sit flat, I'll have to rebuild the floor afterwards.

I'll be looking now to buy a section of floor off a breaker to replace this area.

The chassis leg needs cleaning up and zinc priming still but it's a VW panel so quality is excellent

Whilst getting close to welding this in it occurred to me that when I fit the outer rear arch and corner it could conflict in places, so thought better to fit that first, then the chassis leg. So I've now moved on to that.

I had recently purchased an oversize arch panel from VWH to include the rear corner. It's now cut down to size and sandwiched between the inner tub and rear quarter panel.

One issue though is there's a section on the rear corner which my new panel doesn't cover - my separate rear corner panel doesn't either so will have to fab something up for this.

Once I'm happy with the fit I'll strip and zinc prime the areas to be welded. I think the join between the rear corner and rear panel will need some body solder too to get the look just right.

Last edit: by Hairyarse

Last edit: by Hairyarse

Andy

LINCOLNSHIRE REGION - https://www.facebook.com/groups/467122313360002/

1983 MK1 Golf GTI Campaign Model - Under (looooong) resto!

1962 Rover P4 80

2002 BMW 745i

2008 BMW Z4 2.5Si

LINCOLNSHIRE REGION - https://www.facebook.com/groups/467122313360002/

1983 MK1 Golf GTI Campaign Model - Under (looooong) resto!

1962 Rover P4 80

2002 BMW 745i

2008 BMW Z4 2.5Si

Posted

Website Manager

0 guests and 0 members have just viewed this: None.