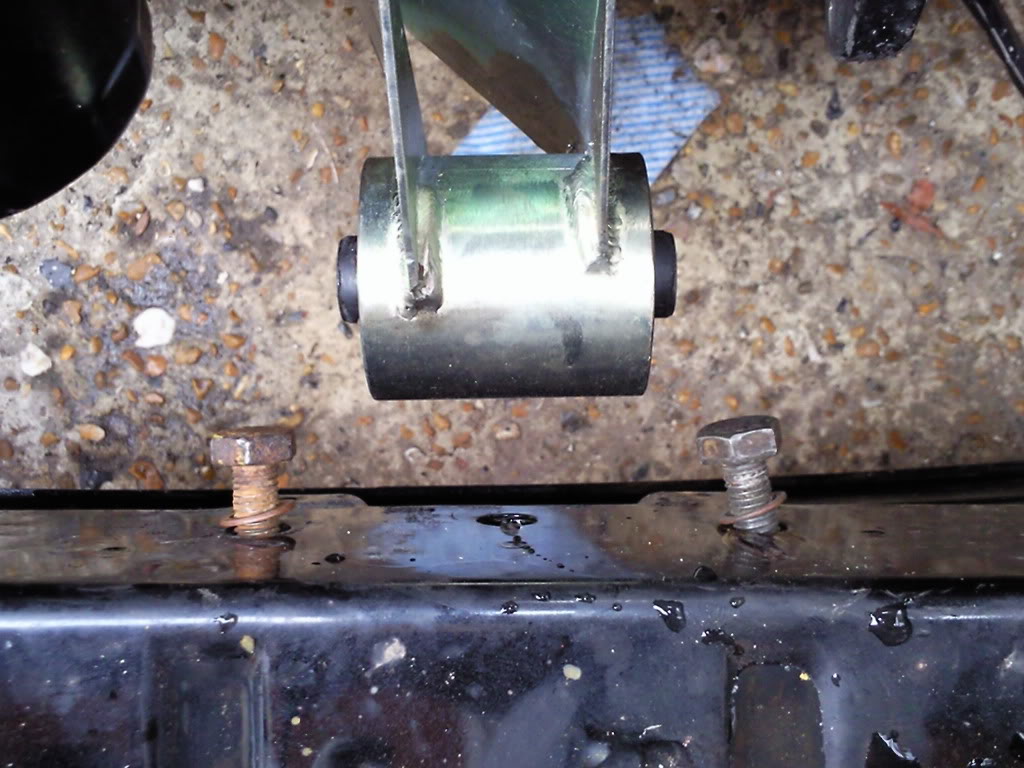

Front engine mount nut damaged

Posted

#1126627

(In Topic #134722)

Settling In

Front engine mount nut damaged

Can anyone give me some advice of the options I have :dontknow:

Absolutely gutted as i thought a brand new panel and mount would get rid of any potential problems like this!

Posted

Local Hero

The bolts should go square into the panel, otherwise the clamping force won't be properly applied. It looks like either your front panel was very poor quality or you managed to cross thread the bolt as it went in - possibly from misaligning it on fitting, due to the aftermarket mount having circular holes and not ovals???

Posted

Settling In

Dont think the panel was at fault although the nut isnt completely central which cant of helped. It is definitely cross threaded. Im going to go buy a tap and die set now and see if i can retap it. Bu there isnt enough space to drill it out first so dont know how it will go…

Posted

Local Hero

- cutting out the area of the panel and putting another section in with a new captive nut

- re-tapping the original thread back into the captive nut

- tapping a slightly larger thread into the captive nut

If its any consolation, that engine mount doesn't actually support any weight, its a 'torque reaction link' and its a common area of weakness for corrosion too. So it isn't subjected to that much load. Having said that, with uprated mounts and fast starts, it will get more load than standard.

Posted

Settling In

Posted

Local Hero

TBH I think you'll be fine with the standard size re-tapped.

Posted

Settling In

Basically I didnt have the option of a good tap as i was home alone. The hardware shop where i work only had a rubbish £20 set that looked like it was made of cheese but thats all i could get. Retapped it as m10 only to find that the tap was genuinely made of cheese and had ruined itself. But it had also flattened most of the thread in the nut. So i managed to retap the nut using the original bolt and got the mount on in the end.

I will be talking personally with the company who made the mount though as the reason it cross threaded in the first place was, just as you said, the two holes drilled in the mount are not big enough for any adjustments and are too close together so the bolts were going in at an angle. Using hammers and blind ignorance I got it on eventually but in future they should definitely make those 2 bolt holes larger like on the original mount, so that there is room to move a few mm left/right. I live local to them so once the caddy runs i might pop down and have a chat in person.

Otherwise im chuffed to bits the engine is all bolted up properly!

0 guests and 0 members have just viewed this: None.