Mk1 gti oil pressure instrument cluster problems

Posted

#1617744

(In Topic #221152)

Settling In

Have traced all cables back to dash and they all bell out ok, replaced high and low oil pressure switches.

Have checked oil pressure its over 4.5 bar.

Have taken clocks out and cleaned all earth points.

While testing the fuel pump relay decided to play up, after testing again it seems that the topran relay coil would only close when the polarity was reversed ??? strange ! anyone else had similar issues? have ordered an OEM relay to try,

Back to the clocks? is there anything else that I could try ? before looking at replacing / repairing the clocks? does anyone have any details of a company that repair clocks?

would be grateful for any advice

Posted

Local Hero

Verify and clean all grounds, that is Battery to frame, and frame to engine. Replace them with 2 off the shelf cables, and Clean the mounting stud, then after attaching the new cables spray with battery corrosion preventative paint.

First thing I would do, is to get a Mechanical gauge on the engine to measure the running pressures.

Verify that your engine oil pressures are good at low and high RPM.

I would then and only then look at the cluster.

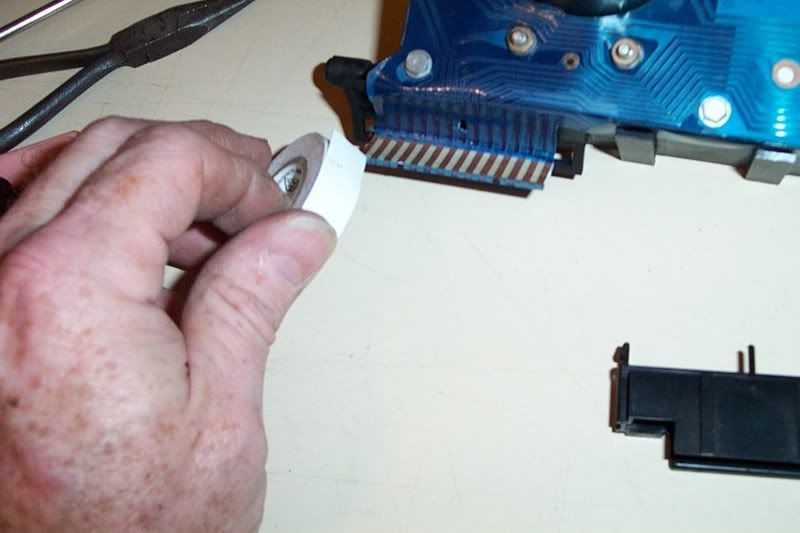

The first thing I would do is to "PLUMP" the connector with one strip of electrical tape over the Tongue of plastic pad side that the Mylar connector is on, tha tis remove the shroud, gently lift the mylar and place a strip of tape on the bad side of the tongue.

On the Brown wire on your cluster connector, I would go about 2 inches back and strip the wire in the middle and attach and solder tape wrap, or use a Scotch-loc wire splicer to add a new ground point directly to the frame of the car behind the cluster in the "X" brace,

The issue is the controller pcb inside the Speedometer housing. it is an "L" shaped PCB and rarely causes issues I have had 4 Cabriolets and a 81 Diesel for 20 years and have never had an issue with that board, but others have.

Finding one may be an issue….I can't help you with clock repairs as I am across the pond so to speak.

What do Divorces, Great Coffee, and Car Electrics all have in common?

They all start with GOOD Grounds.

Where are my DIY Links?

They all start with GOOD Grounds.

Where are my DIY Links?

Posted

Local Hero

The reason I ask is that when I fitted a 2.0L pump to my cabriolets 2h 1.8's I had to use the original oil pickup tube from the old pump on the new on mine as the fitment of the oil pan (sump) had issues with Clearance of the pickup tube bottoming out in the pan and stopping it from attaching correctly.

What do Divorces, Great Coffee, and Car Electrics all have in common?

They all start with GOOD Grounds.

Where are my DIY Links?

They all start with GOOD Grounds.

Where are my DIY Links?

Posted

Old Timer

And as a side issue, I've had problems in the past with non-genuine senders and relays, Topran are not the best in my opinion (but I know getting genuine stuff these days is becoming more and more difficult).

Nut & Bolt Resto Complete (Mars Red GTi original): https://vwgolfmk1.org.uk/forum/index.php?page=topicview&type=misc&id=projects%2Fyour-mk1-golfs_2%2Fpistolpete-s-mars-red&start__keyed=

Nut & Bolt Resto in Progress (Lhasa 16v): https://vwgolfmk1.org.uk/forum/index.php?page=topicview&type=misc&id=projects%2Fyour-mk1-golfs_2%2Fpistolpete-s-lhasa&redirected=1

Nut & Bolt Resto in Progress (Lhasa 16v): https://vwgolfmk1.org.uk/forum/index.php?page=topicview&type=misc&id=projects%2Fyour-mk1-golfs_2%2Fpistolpete-s-lhasa&redirected=1

0 guests and 0 members have just viewed this: None.