Method for measuring fuel pump current flow (amps) ?

Posted

#932655

(In Topic #110047)

Settling In

Method for measuring fuel pump current flow (amps) ?

Thought that but substituting the fuse in the pump relay with my test meter probes would work but the car wouldn't start like that, as soon as I replaced the fuse it did.

Do I have to removed the pump relay & bridge the perm live feed & fuel pump terminals with test meter ?

Posted

Old Timer

The circuit would be

Fuel pump + terminal -> red lead of ammeter, neg lead of ammeter -> earth

Although in actual fact you dont need to connect it there at all, you could just connect it to the pos end of the battery, and do a bit of math, but thats probably just as complicated in a different way and you would need a meter capable of higher currents.

I have to ask why you'd want to measure current though, as usually all you need to do is check wether it works or not, unless its popping fuses, in which case it could be crap in the tank putting pressure on the motor, or could possibly getting stuck (aka its faulty)

Hope that helps anyway.

~Madferret

Mk1 1457cc 5door GX '83

Mk1 1457cc 5door GX '83

Posted

Settling In

Madferret said

I have to ask why you'd want to measure current though, as usually all you need to do is check wether it works or not, unless its popping fuses, in which case it could be crap in the tank putting pressure on the motor, or could possibly getting stuck (aka its faulty).

I've fallen into the trap of replacing too many parts at once & not finding it easy to find where the problem is.

1.6GTI EG engine with rebuilt head & Newman PH2 cam, 4 x new injectors, braided fuel hoses & accumulator + used but said to work AAV.

Can get a good steady idle using a Gunsons CO meter to get a reading of 1.5 (spec is 1 - 2 & the Gunsons says it has a poss error of + or - .5) at tickover set to 1000 revs with headlamps, spots & rad fan running).

Car struggles to rev even in neutral & will hardly pull first gear, throttle body butterflies open fully when accelerator pedal depressed & the airflow plate in the metering head isn't sticking.

I'm sure that I have the crank, inter & camshaft pulleys aligned correctly (I changed the cambelt last year with no probs so understand how it is supposed to lign up).

Checked the compression & all above 155, values are higher than those I took before the head was rebuilt, assume I have a little bore / ring wear but it ran before.

Haven't got an adjustable cam sprocket although Newmans website says little to be gained on PH1 / PH2 spec camshafts by using one.

Timed the engine at TDC with the vac line on (as is spec on EG engine).

I'm thinking the problem lies with the fuel supply, Crazy Quiff is very hard to get hold of as want to order one of his fuel pressure test kits… left messages & waiting for a call back. Reading prowlers injector test he says make sure pump is working correctly first.

So I was going to do an output test to see what it flowed (petrol volume) & my understanding was that by also checking the current the fuel pump was pulling it might show up something like a blockage in the system, ie maybe an obstruction in one of the new braided lines fuel lines.

Before rebuild car ran fine with exception of old AAV being stuck shut & had just started having problems with warm start. Felt like treating it to new injectors & seals, found a holed / rusty fuel line under car so ordered Crazy's kit & ended up biting the bullet & getting a new gen accumulator as the old ones pipe connectors looked like they had been under the sea for 20+ years.

Have disturbed the fuel pump a bit as was held on by cable ties (prev owner) so fitted one of Crazy's stainless brackets.

Posted

Local Hero

Posted

Settling In

paul_c said

Whereabouts are you located? You tend to only need to do a fuel pressure test once, then it stays set. So might be worth finding another club member who has one local to you, rather than buying the fuel pressure kit, etc?

Northampton.

Good point re how many times will use it but I've ordered the kit off his website this morning so…

Also fitted a stainless 4 branch exhaust manifold & new fuel filter.

New dizzy cap & rotor late last year & about a month back fitted a set of Magnecor leads as I was less than happy with the GSF Beru ones… Did a few hundred miles with the Magnecors before stripping it down so I know they work fine.

Do think its fuel related but if not at least I would prove factually that things are in spec before looking elsewhere.

At idle by feathering the throttle can reluctanly get revs to go to 4k but no more, bliping the throttle just seems to be very flat unresponsive. No nasty noises from the top end following rebuild & when timing I did a 'crude' check of a tdc test on #1 cyl by inserting a long allen key down the spark plug hole, it did corresponded with how I set the pulleys & cam sprocket re alignment marks.

Newman cam has been shimmed to their correct spec.

Posted

Settling In

Found the problem, good info in here...

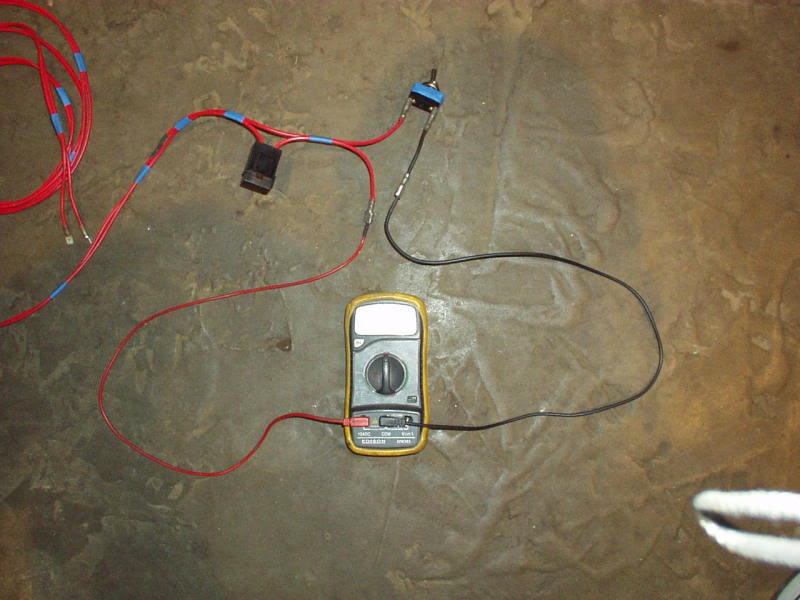

As it was my intention to do Prowlers test I modified the fuel pump relay jumper leads to include a Digital Multimeter (DMM) for the purpose of measuring the current draw of the pump at the same time. Leads are connected into the COM & 10ADC ports.

First test was to check the amount of petrol the pump would flow in 30 secs, Haynes manual said to disconnect the return flow line (back to the petrol tank) at the metering head which I did & by temp relocating the coolant expansion tank a nice hole for a 2ltr bottle was created. The fuel pump relay is removed & the 2 tails from my wiring test loom were inserted into L13 & L14.

Read a spec that current draw should be in the range 5-8 amps.

5.6 amps current draw & 1300cc of fluid obtained in 30 sec, Haynes says pump with screw connectors should flow 900cc min.

Interestingly when I re connected the return flow line & ran the pump the current draw increased to 8.25 amps, slightly above spec.

Bit of Prowling.

Current draw when the injectors were spraying was 7.9 amps.

Can't argue with the results.

I had been supplied 4 new injectors of 2 different sorts, RCI-015 which didn't have air shrouds on the bottom & RCI-045 which did & I'd had to remove the air shrounds so they would fit into my injector seats. If I lifted the air sensor plate just a fraction to start the injectors spraying the 2 that had the air shrouds removed (RCI-045) would drip slightly & only produce a spray pattern when the plate was lifted slightly more… wasn't impressed with that.

Next onto system pressure test (using a K jet system pressure test kit), won't go into depth on the method as its all on this forum anyway if you search. The cold control pressure at the ambient temp in the bay should have been no more that 25psi, the test gauge was off the dial at 100psi +. Likewise the warm control pressure test which should have been between 49 & 57 psi was off the dial at 100psi+. At that moment I though the warm up regulator was at fault but performing the system pressure test this reading was also 100psi + (spec 65-75).

Got to be the Pressure regulating valve in the metering head I was thinking, took it out cleaned & inspected, refitted but no reduction in fuel pressure when re testing (did warm control & system pressure only as engine was up to temp).

It was then I remembered the slightly higher reading of the fuel pump current draw when I had reconnected the return flow to the tank.

As an experiment I disconnected the return flow at the metering head & feed it into the bottle I had prev used as a catch tank. Being very careful & using Mrs Strangeways as a spotter I ran the engine & straight away all pressures spot on & engine reving / behaving like it should do.

Fault is either a restriction in the new braided fuel hose (manufacturing or how I've routed it) or the small rubber pipe between the end of the new braided hose & the tank itself.

Ran out of time to solve that this eve but hope this post helps some one out. You can use the current draw from the pump to check for blockages in different elements of the system ie fuel filter with a bit of thought to where in the system you allow the fuel to run freely into a catch tank.

Posted

Settled In

Re: Found the problem, good info in here...

strangewayz said

Summary of prob being a lot of new parts fitted (see above for more details) & whilst the car would tickover it was reluctant to rev & wouldn't even pull 1st gear enough to change into 2nd..

As it was my intention to do Prowlers test I modified the fuel pump relay jumper leads to include a Digital Multimeter (DMM) for the purpose of measuring the current draw of the pump at the same time. Leads are connected into the COM & 10ADC ports.

First test was to check the amount of petrol the pump would flow in 30 secs, Haynes manual said to disconnect the return flow line (back to the petrol tank) at the metering head which I did & by temp relocating the coolant expansion tank a nice hole for a 2ltr bottle was created. The fuel pump relay is removed & the 2 tails from my wiring test loom were inserted into L13 & L14.

Read a spec that current draw should be in the range 5-8 amps.

5.6 amps current draw & 1300cc of fluid obtained in 30 sec, Haynes says pump with screw connectors should flow 900cc min.

Interestingly when I re connected the return flow line & ran the pump the current draw increased to 8.25 amps, slightly above spec.

Bit of Prowling.

Current draw when the injectors were spraying was 7.9 amps.

Can't argue with the results.

I had been supplied 4 new injectors of 2 different sorts, RCI-015 which didn't have air shrouds on the bottom & RCI-045 which did & I'd had to remove the air shrounds so they would fit into my injector seats. If I lifted the air sensor plate just a fraction to start the injectors spraying the 2 that had the air shrouds removed (RCI-045) would drip slightly & only produce a spray pattern when the plate was lifted slightly more… wasn't impressed with that.

Next onto system pressure test (using a K jet system pressure test kit), won't go into depth on the method as its all on this forum anyway if you search. The cold control pressure at the ambient temp in the bay should have been no more that 25psi, the test gauge was off the dial at 100psi +. Likewise the warm control pressure test which should have been between 49 & 57 psi was off the dial at 100psi+. At that moment I though the warm up regulator was at fault but performing the system pressure test this reading was also 100psi + (spec 65-75).

Got to be the Pressure regulating valve in the metering head I was thinking, took it out cleaned & inspected, refitted but no reduction in fuel pressure when re testing (did warm control & system pressure only as engine was up to temp).

It was then I remembered the slightly higher reading of the fuel pump current draw when I had reconnected the return flow to the tank.

As an experiment I disconnected the return flow at the metering head & feed it into the bottle I had prev used as a catch tank. Being very careful & using Mrs Strangeways as a spotter I ran the engine & straight away all pressures spot on & engine reving / behaving like it should do.

Fault is either a restriction in the new braided fuel hose (manufacturing or how I've routed it) or the small rubber pipe between the end of the new braided hose & the tank itself.

Ran out of time to solve that this eve but hope this post helps some one out. You can use the current draw from the pump to check for blockages in different elements of the system ie fuel filter with a bit of thought to where in the system you allow the fuel to run freely into a catch tank.

have you fixed the car and if so how m8 cheers as my car will start but struggles to rev on full throttle

<a href="http://s277.photobucket.com/albums/kk54/tamthebam16v/?action=view¤t=05092008653-1.jpg"><img src="http://i277.photobucket.com/albums/kk54/tamthebam16v/05092008653-1.jpg" border="0" alt="Photobucket"></a>

<a href="http://s277.photobucket.com/albums/kk54/tamthebam16v/?action=view¤t=05092008653-1.jpg"><img src="http://i277.photobucket.com/albums/kk54/tamthebam16v/05092008653-1.jpg" border="0" alt="Photobucket"></a>

Posted

Settled In

The meter reads the amps via the electro magnetic field generated by the current flow through the live wire. (the meter will not work if the clamp is also around the negative/earth)

MK1 83 Jetta… 2ltr 16v ACE

MK1 88 caddy pickup 20VT soon

MK2 Golf 90spec 2ltr ABF coming soon

T5 TDI

MK1 88 caddy pickup 20VT soon

MK2 Golf 90spec 2ltr ABF coming soon

T5 TDI

0 guests and 0 members have just viewed this: None.