Installation of belt-side engine mount on DX block

Posted

#1579784

(In Topic #213246)

Settled In

Looking for some advice on refitting the belt-side engine mount to a DX block. It's been off for a long while but I'm trying to put it back with the correct type of cambelt backing plate and top cover.

I've found this picture on Vortex which seems to show that the mount goes on first and then the backing plate over the top of it.

However this drawing in ETKA shows a small two-hole spacer plate fitted on as well. From the drawing this should go over the top of the backing plate - so isn't in the previous picture.

I've got hold of one of these plates - it was a right pain as it's discontinued! - but I was a bit surprised because I was expecting it to go directly against the block, under the mount, so the dogleg portion of the engine mount was supported when doing up its front two mounting bolts. It's become obvious that the block lifting eye / alternator mount goes on underneath the engine mount instead. But should the spacer plate be fitted or left off? I'm intending to use a metal upper cambelt cover if that makes any difference.

Could someone give me a steer, please? Thanks in advance

Nick

Last edit: by Stone

Last edit: by Stone

"Klaus": 1987 Clipper Cabrio, LA7Y, 1.8 Weber (auto)

1995 Corrado VR6, LK4Z: RIP

2003 Golf R32, LB5R

1995 Corrado VR6, LK4Z: RIP

2003 Golf R32, LB5R

Posted

Settled In

This thing is like a jigsaw puzzle! It's not helping that the parts all differ from the ones online…was there a later alternator mount that wraps around the side of the block rather than being in two pieces? Should I be using that one?

Nick

"Klaus": 1987 Clipper Cabrio, LA7Y, 1.8 Weber (auto)

1995 Corrado VR6, LK4Z: RIP

2003 Golf R32, LB5R

1995 Corrado VR6, LK4Z: RIP

2003 Golf R32, LB5R

Posted

Local Hero

Two great tips for you, one is for the replacement of the bolts on the rear of the mounting bracket with grade 8.8 or 10 hex headed bolts of the same length. It makes it easier to get on or off while the engine is mounted in the car

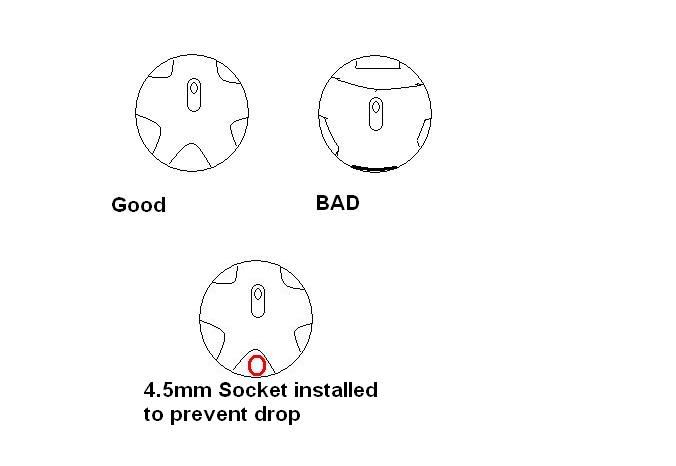

On the mount itself I usually suggest the use of a sacrificial socket (6mm works) but have taken to placing a bit of the old mount I mean it is rubber.

The placement of the bit, or rubber is at the top of the mount. It prevents the mount from bottoming out when it decides to give up the ghost.

By stopping the Drop of the engine you prevent other things from happening like the tranny linkaes from binding… Yes you still get the excessive vibration of a bad mount, you just usually don't get the loud bang on the mount when hitting a pot hole.

This is the socket pic and it is upside down.

What do Divorces, Great Coffee, and Car Electrics all have in common?

They all start with GOOD Grounds.

Where are my DIY Links?

They all start with GOOD Grounds.

Where are my DIY Links?

Posted

Settled In

It looks like I do need the later alternator mount as the hole in the belt cover doesn't line up so there's no way to install the bolt. It's a super early block (so much so that it doesn't have the extra protrusion for the alignment holes for the head gasket on top!) but the head must be more recent as it has both upper and lower bolt holes for the top half of the mount. However the bits I got with it are all the old style - no rack and pinion adjustment on the alternator's top mount, for example. All good fun

"Klaus": 1987 Clipper Cabrio, LA7Y, 1.8 Weber (auto)

1995 Corrado VR6, LK4Z: RIP

2003 Golf R32, LB5R

1995 Corrado VR6, LK4Z: RIP

2003 Golf R32, LB5R

Posted

Settled In

As you can see with it test fitted this all lines up nicely now and the Allen headed bolt around which the alternator pivots can be retrieved through the hole in the plate when required.

Unfortunately for me I didn't figure this out until after I drilled an access hole in the backing plate to allow access to the mounting bolt on the other style of alternator bracket, so now I'm waiting for Heritage to hurry up and deliver me a new backing plate before I can get the head fitted. Ho-hum. At least I got there in the end!

"Klaus": 1987 Clipper Cabrio, LA7Y, 1.8 Weber (auto)

1995 Corrado VR6, LK4Z: RIP

2003 Golf R32, LB5R

1995 Corrado VR6, LK4Z: RIP

2003 Golf R32, LB5R

0 guests and 0 members have just viewed this: None.