Change Indicator & Econo-meter - GTi's

Posted

#691136

(In Topic #83416)

Settled In

Change Indicator & Econo-meter - GTi's

This thread finds its origins in the "Hall Sender - 99.9mpg" thread but I thought I'd break this out in order to separate the two topics.

I'll address this in two sections - the change indicator and the econo-meter.

The Change Indicator has two inputs - one mechanical, the other electrical. The Change Indictaor is only functional in gears 1 through 4.

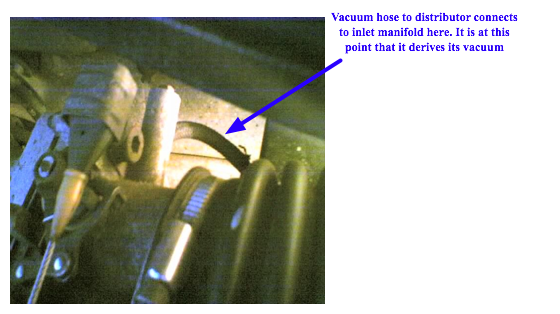

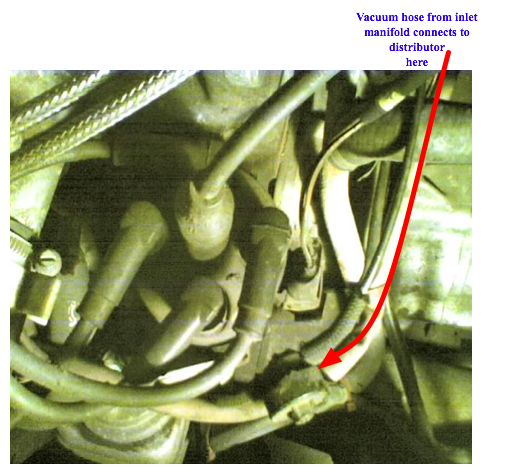

The mechanical input is via a vacuum tube that connects from the rear of the inlet manifold to the vacuum driven advance / retard function on the distributor.

The vacuum advance / retard may be regarded as a "fine tune" on the timing function. The "course tune" is provided by two spring loaded weights (governors) that migrate inwards and outwards dependent on the speed of rotation of the distributor shaft. The faster the rotation, the further the governors migrate. As the governors move they cause the contact plate in the distributor to rotate thus adjusting the timing.

The "fine tuning" to this is vacuum driven. As the vacuum in the inlet manifold increases, the vacuum tube from the inlet manifold to the distributor vacuum unit causes a diaphragm in the vacuum unit at the base of the distributor to expand. This in turn adjusts the position of the distributor contact plate thus adjusting the timing.

Linking this to the change indicator - as the diaphragm in the distributor vacuum unit expands, it causes an electrical circuit to open which sends a signal to the change indicator on the dashboard. This normally occurs at circa 2000 rpm with this rotation speed being taken from the speed of rotation of the distributor shaft. It is possible to adjust the the point at which this circuit opens by using the adjustment screw located on the distributor vacuum unit .

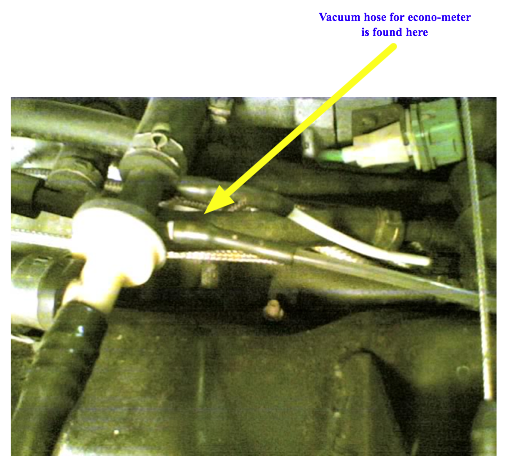

The following two photographs provide further detail on the location of the vacuum tube/inlet manifold and vacuum tube/distributor vacuum unit.

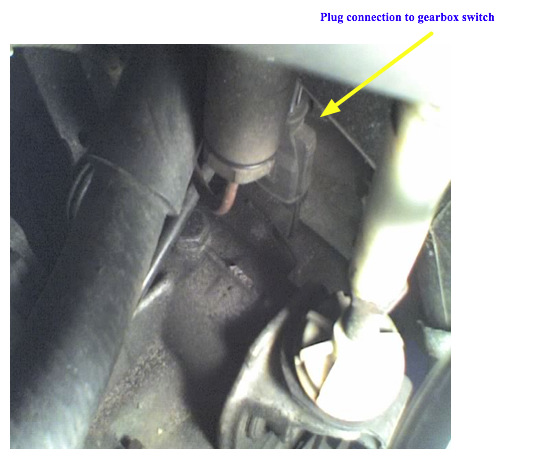

The Econo-meter is vacuum driven and is linked to a switch on the top of the gearbox. The econo-meter is only functional in 5th gear.

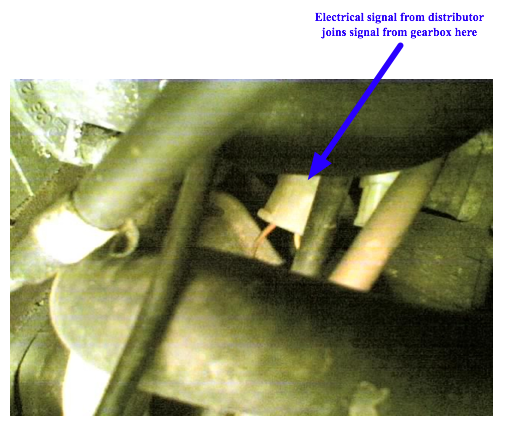

When 5th gear is selected, the switch in the gearbox disconnects the electrical signal from the distribitor vacuum unit and activates the econo-meter needle. The econo-meter needle is purely vacuum driven with the source of this vacuum being derived from the inlet manifold.

The following photographs show the position of the switch on the gearbox, the connector where the input from the distributor vacuum unit and the output from the gearbox switch combine and the location of the econo-meter needle vacuum tube.

Hope this helps.

MP

1 guests and 0 members have just viewed this: None.