MIG wire feed set up

Posted

Settled In

MIG wire feed set up

I should have taken pics when I changed the wire on mine on saturday. The wire feed tube on the 130 is soft plastic and can kink and stretch really easily at the point where it comes out of the welder. I had a point on mine where the line was kinked really badly so it was like the tube was gripping the wire. This made the wire feed motor appear to be pulsing and it was impossible to get a constant wire speed. Absolutley impossible to weld with.

I changed the wire feed tube for a PTFE tube which was twice as expensive as the standard one but is less friction. I just need to watch out and not kink it again. The motor seems to be feeding smoothly again.

Baz

Posted

Local Hero

Where did you get the PTFE one from?

Cheers

Andy

Andy

LINCOLNSHIRE REGION - https://www.facebook.com/groups/467122313360002/

1983 MK1 Golf GTI Campaign Model - Under (looooong) resto!

1962 Rover P4 80

2002 BMW 745i

2008 BMW Z4 2.5Si

LINCOLNSHIRE REGION - https://www.facebook.com/groups/467122313360002/

1983 MK1 Golf GTI Campaign Model - Under (looooong) resto!

1962 Rover P4 80

2002 BMW 745i

2008 BMW Z4 2.5Si

Posted

Settled In

It's about 2-3 times as expensive as the normal black one but i'm hoping it lasts longer.

Baz

Posted

Local Hero

Andy

LINCOLNSHIRE REGION - https://www.facebook.com/groups/467122313360002/

1983 MK1 Golf GTI Campaign Model - Under (looooong) resto!

1962 Rover P4 80

2002 BMW 745i

2008 BMW Z4 2.5Si

LINCOLNSHIRE REGION - https://www.facebook.com/groups/467122313360002/

1983 MK1 Golf GTI Campaign Model - Under (looooong) resto!

1962 Rover P4 80

2002 BMW 745i

2008 BMW Z4 2.5Si

Posted

Old Timer

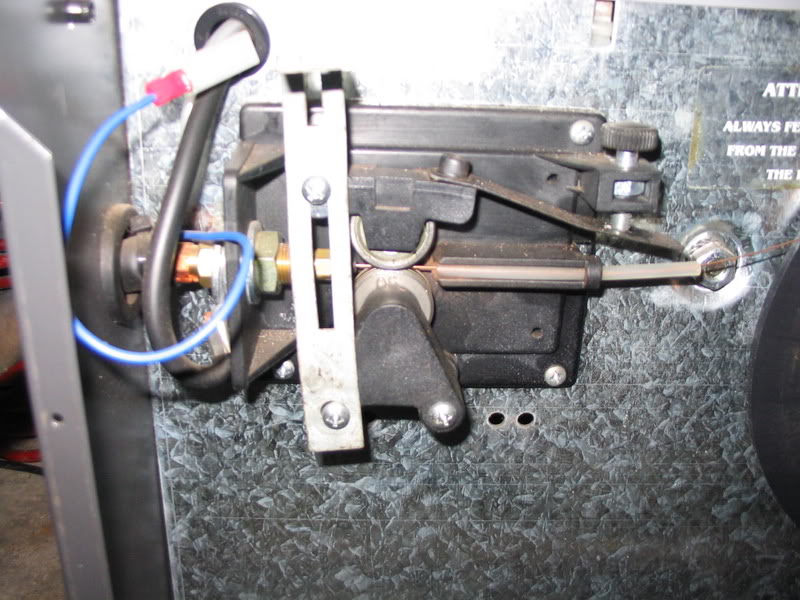

I had problems with my wire feed from new too. Mines a SIP Turbo 105, basically the same as the 130 just a bit weedier.

I modded/bodged mine to get the rollers to pinch the wire properly and this improved things no end. The naff pastic flexes and the rollers don't sit flat against each other.

The only other mod I've done is change the gas regulator to allow the 1KG refillable sealey bottles available from my local motorfactor/sealey stockist. I used the original regulator first on the new bottles but it didnt open the bottles valve up even when turned fully open.

Hope this helps and good luck with the resto. Looks like you're getting well stuck in now

Also forgot to say… The larger wire reel is fitted and I find feeding the wire in from the top is best too. The screw that holds the reel on in place comes undone though as it turns the reel the anticlockwise. I bodged this too with some washers somehow and it rarely happens now.

Posted

Secretary

First Golf, lots of work. I've started so I'll finish!

Posted

Local Hero

Andy

LINCOLNSHIRE REGION - https://www.facebook.com/groups/467122313360002/

1983 MK1 Golf GTI Campaign Model - Under (looooong) resto!

1962 Rover P4 80

2002 BMW 745i

2008 BMW Z4 2.5Si

LINCOLNSHIRE REGION - https://www.facebook.com/groups/467122313360002/

1983 MK1 Golf GTI Campaign Model - Under (looooong) resto!

1962 Rover P4 80

2002 BMW 745i

2008 BMW Z4 2.5Si

Posted

Local Hero

Want to try to ensure not too much or too little

Cheers

Andy

Andy

LINCOLNSHIRE REGION - https://www.facebook.com/groups/467122313360002/

1983 MK1 Golf GTI Campaign Model - Under (looooong) resto!

1962 Rover P4 80

2002 BMW 745i

2008 BMW Z4 2.5Si

LINCOLNSHIRE REGION - https://www.facebook.com/groups/467122313360002/

1983 MK1 Golf GTI Campaign Model - Under (looooong) resto!

1962 Rover P4 80

2002 BMW 745i

2008 BMW Z4 2.5Si

Posted

Local Hero

Hairyarse said

…one last question. For anyone using the same MIG as mine, or at least a 130amp machine, what power setting do you use on your MK1? I had mine on medium.

Want to try to ensure not too much or too little

Cheers

Andy

How many power settings does the machine have, I thought it had 6 settings?

Posted

Settled In

Posted

Local Hero

Posted

Local Hero

Andy

LINCOLNSHIRE REGION - https://www.facebook.com/groups/467122313360002/

1983 MK1 Golf GTI Campaign Model - Under (looooong) resto!

1962 Rover P4 80

2002 BMW 745i

2008 BMW Z4 2.5Si

LINCOLNSHIRE REGION - https://www.facebook.com/groups/467122313360002/

1983 MK1 Golf GTI Campaign Model - Under (looooong) resto!

1962 Rover P4 80

2002 BMW 745i

2008 BMW Z4 2.5Si

0 guests and 0 members have just viewed this: None.