Mk1 16vg60 build, slowly but surely

Posted

Old Timer

The finished result will be well worth all the effort.

Really looking forward to seeing it up and running

Posted

Old Timer

I'm actually almost in possession of everything I need to make the car run once my latest order arrives.

Thankfully no one tells you exactly what your going to spend on it at the beginning do they ha ha.

Posted

Old Timer

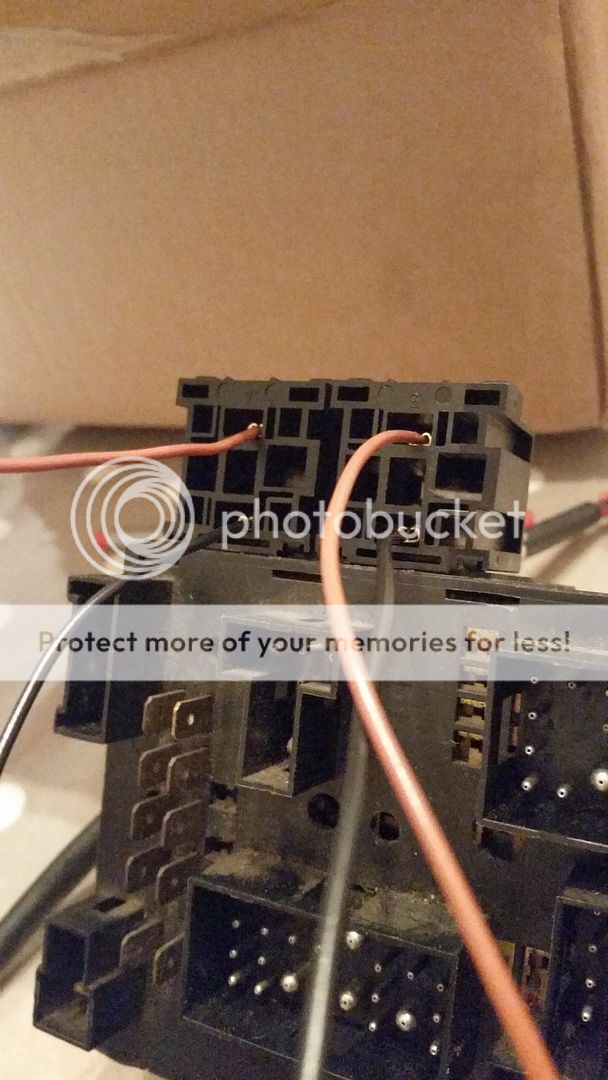

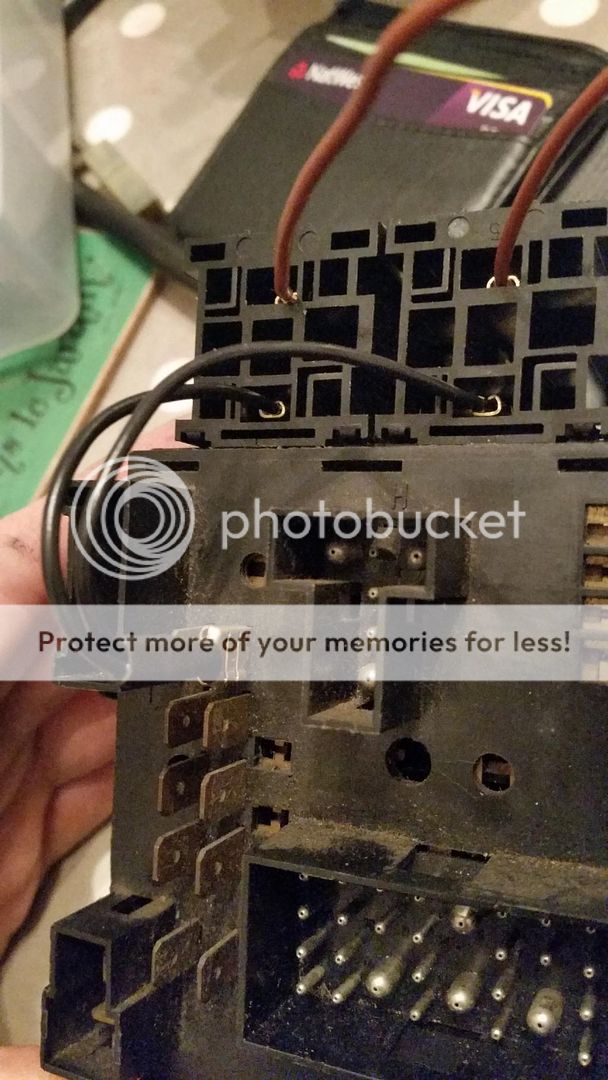

Decided it was going to be best to replace this along with the main earth's and ignition switch feed and return.

Other jobs included replacing the alternator exciter wire. I purchased a couple of universal connector removal tools hoping they would remove the large and small pins from the fuse box. One of them worked on the smaller pins

Getting there with the crimps

Made a start on wiring in two relay holders for my ECU and Lambda sensor

Nothing very exciting just yet but it's progress

Last edit: by daniboy123

Last edit: by daniboy123

Posted

Old Timer

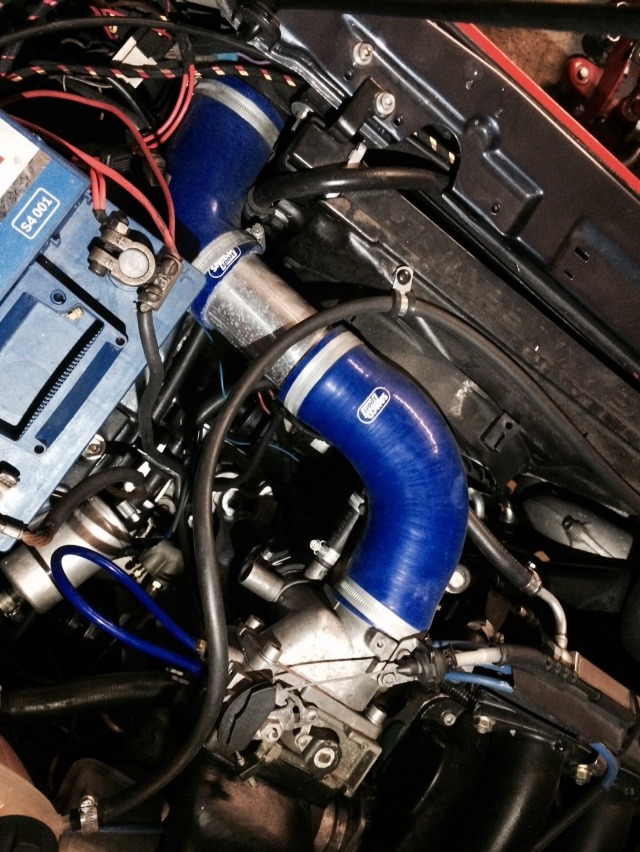

What are other people's experiences with G60 induction kits?

Ideally I'd have used some kind of heat shield as well but things are looking a bit tight down there.

Another thing I'm on the lookout for is a compact washer bottle/pump to fit in the scuttle area. Anyone come across anything like this?.

Last edit: by daniboy123

Last edit: by daniboy123

Posted

Old Timer

Obviously if you have no other choice a cotton filter is the way to go. Do not use a foam filter as these let in a lot of particulates.

Im using the stock Honda prelude paper cone filter in my car at the moment until I can modify my standard airbox to fit. The Honda s2000 also uses a paper cone filter but I would image that you will be consuming a fair few cfm of air than it could cope with.

Posted

Old Timer

Posted

Website Manager

http://www.knfilters.co.uk/apollo.aspx

Posted

Old Timer

What flange have you both used to get from the charger inlet to the air intake?

Posted

Old Timer

The engine has had to come apart yet again as I noticed some swarf had made its way into a few of the exhaust ports, just sloppiness on my behalf

Whilst apart I noticed that there are still score marks in the bores which I believe are being caused by the cutouts in the cylinder block having not being chamfered after the rebore. They are catching the pistons which are then causing marks in the bores. Im glad ive noticed it now really but it was disheartening stripping everything apart for the 3rd time.

Its going back to the engine builders and im having the bores rechamfered and rehoned along with soda blasting and repainting as I wasn't happy with my hand painted finish.

No pictures unfortunately as im writing this at work offshore but ill be posting some once I return home and collect my engine block.

Ive also had my inlet manifold fitted with dowls and the head drilled to accept them in order to ensure it goes on correctly each time as it was originally a poor fit and id had to file out some material from the cylinder head to ensure free airflow into the engine. The machine shop blended the intake ports in at the same time. They checked my hydraulic tappets and KR camshafts and discovered the cams were out of wear limits along with 6 tappets.

Ive purchased a new set of lightweight tappets from Bar-Tek in Germany;

http://www.bar-tek-tuning.com/cgi-bin/cosmoshop/lshop.cgi?action=showdetail&wkid=17255&ls=en&nc=1432803145-18956&rubnum=&artnum=2116016&file=10&gesamt_zeilen=0Tsuche--16vg60

Ive also been considering my camshaft options. Replacement KR or ABF cams would be econominal but I might end up with another worn set.

Ive found these and wondered what other people thought;

http://www.bar-tek-tuning.com/cgi-bin/cosmoshop/lshop.cgi?action=showdetail&wkid=17255&ls=en&nc=1432803597-19598&rubnum=&artnum=2216g601&file=2&gesamt_zeilen=0Tsuche--16vg60%20camshaft

Posted

Old Timer

The engine has had to come apart yet again as I noticed some swarf had made its way into a few of the exhaust ports, just sloppiness on my behalf

Whilst apart I noticed that there are still score marks in the bores which I believe are being caused by the cutouts in the cylinder block having not being chamfered after the rebore. They are catching the pistons which are then causing marks in the bores. Im glad ive noticed it now really but it was disheartening stripping everything apart for the 3rd time.

Its going back to the engine builders and im having the bores rechamfered and rehoned along with soda blasting and repainting as I wasn't happy with my hand painted finish.

No pictures unfortunately as im writing this at work offshore but ill be posting some once I return home and collect my engine block.

Ive also had my inlet manifold fitted with dowls and the head drilled to accept them in order to ensure it goes on correctly each time as it was originally a poor fit and id had to file out some material from the cylinder head to ensure free airflow into the engine. The machine shop blended the intake ports in at the same time. They checked my hydraulic tappets and KR camshafts and discovered the cams were out of wear limits along with 6 tappets.

Ive purchased a new set of lightweight tappets from Bar-Tek in Germany;

http://www.bar-tek-tuning.com/cgi-bin/cosmoshop/lshop.cgi?action=showdetail&wkid=17255&ls=en&nc=1432803145-18956&rubnum=&artnum=2116016&file=10&gesamt_zeilen=0Tsuche--16vg60

Ive also been considering my camshaft options. Replacement KR or ABF cams would be econominal but I might end up with another worn set.

Ive found these and wondered what other people thought;

http://www.bar-tek-tuning.com/cgi-bin/cosmoshop/lshop.cgi?action=showdetail&wkid=17255&ls=en&nc=1432803597-19598&rubnum=&artnum=2216g601&file=2&gesamt_zeilen=0Tsuche--16vg60%20camshaft

Posted

Old Timer

Hi Dandaniboy123 said

Ive decided to stick with a stock G60 airbox for the induction side of things, the bodyshop my car is with are going to make it fit on the chassis leg which will require a bit of modification.

The engine has had to come apart yet again as I noticed some swarf had made its way into a few of the exhaust ports, just sloppiness on my behalf.

Whilst apart I noticed that there are still score marks in the bores which I believe are being caused by the cutouts in the cylinder block having not being chamfered after the rebore. They are catching the pistons which are then causing marks in the bores. Im glad ive noticed it now really but it was disheartening stripping everything apart for the 3rd time.

Its going back to the engine builders and im having the bores rechamfered and rehoned along with soda blasting and repainting as I wasn't happy with my hand painted finish.

No pictures unfortunately as im writing this at work offshore but ill be posting some once I return home and collect my engine block.

Ive also had my inlet manifold fitted with dowls and the head drilled to accept them in order to ensure it goes on correctly each time as it was originally a poor fit and id had to file out some material from the cylinder head to ensure free airflow into the engine. The machine shop blended the intake ports in at the same time. They checked my hydraulic tappets and KR camshafts and discovered the cams were out of wear limits along with 6 tappets.

Ive purchased a new set of lightweight tappets from Bar-Tek in Germany;

http://www.bar-tek-tuning.com/cgi-bin/cosmoshop/lshop.cgi?action=showdetail&wkid=17255&ls=en&nc=1432803145-18956&rubnum=&artnum=2116016&file=10&gesamt_zeilen=0Tsuche--16vg60

Ive also been considering my camshaft options. Replacement KR or ABF cams would be econominal but I might end up with another worn set.

Ive found these and wondered what other people thought;

http://www.bar-tek-tuning.com/cgi-bin/cosmoshop/lshop.cgi?action=showdetail&wkid=17255&ls=en&nc=1432803597-19598&rubnum=&artnum=2216g601&file=2&gesamt_zeilen=0Tsuche--16vg60%20camshaft

sorry to hear you had to split your engine. It's really disheartening when things like this happen. I had to split the engine when an exhaust stud snapped but meant I could port and polish the head whilst it was off

I have been working on a little project of my own air box wise. I might have a better solution for your induction. I'm just uploading pics. Keep an eye on my build as I will have an update in a moment.

Cheers

Rich

Posted

Old Timer

I don't know what space you have to play with considering you have a 16vG60 but seems to work well with a 8vG60

Posted

Old Timer

That looks like a neat solution to drawing cold air into the engine bay. Ive removed the washer bottle bracket from the inner wing which allows me to position the G60 airbox right uptight against the inner wing and provides just enough clearance for the serp belt, it is tight mind.

Another thing im on the lookout for is a specialist that can make up bespoke intercooler/cooling piping. Ive decided its going to be much easier and quicker to have a professional do this rather that ordering loads of tubing and silicone that isn't quite right.

If anyone knows of a company that can do a good job of this kind of work, ideally in the north east id appreciate any pointers, cheers.

Posted

Old Timer

daniboy123 said

Another thing I'm on the lookout for is a compact washer bottle/pump to fit in the scuttle area. Anyone come across anything like this?.

I have a 'bag' type washer bottle which is pretty neat and takes up almost no space (also has next to no capacity lol). No idea where it came from but I can post up some pics later. It has an integrated pump and uses the loom plug from the OEM washer bottle so it's just a case of unplugging the electrical connection and swapping the hose over to fit.

Posted

Old Timer

Ive been speaking to a couple of specialists about fabricating my intercooler and coolant pipework for me but they said they would need an idea of how tight things were before they would commit to the job. Do you have any pictures of your charger pipework going to and from your intercooler that you could post up at all? Im using a laminova water/oil cooler so my coolant pipework will be totally different to yours.

Posted

Old Timer

http://www.ebay.co.uk/itm/like/370634015139?limghlpsr=true&hlpv=2&ops=true&viphx=1&hlpht=true&lpid=108&chn=ps&device=c&rlsatarget=&adtype=pla&crdt=0&ff3=1&ff11=ICEP3.0.0-L&ff12=67&ff13=80&ff14=108&ff19=0

Probably less hassle and it takes up very little space underneath the edge of the wing

No probs to get you some pics of the bay later. Did you consider getting an exhaust shop to do your intercooler pipework? Custom pipework should be second nature to them.

I quite fancy one of those Laminova coolers myself so I can go back to a standard front bumper and I'm about to install my twin core mk2 16v rad to add some extra cooling over the single core one that I currently have.

Last edit: by Mike 16vG60

Last edit: by Mike 16vG60

Posted

Old Timer

I have an exhaust specialist near me so ill contact them about it aswell.

The pictures will be a big help, thanks

Posted

Old Timer

I have an exhaust specialist near me so ill contact them about it aswell.

The pictures will be a big help, thanks

Posted

Old Timer

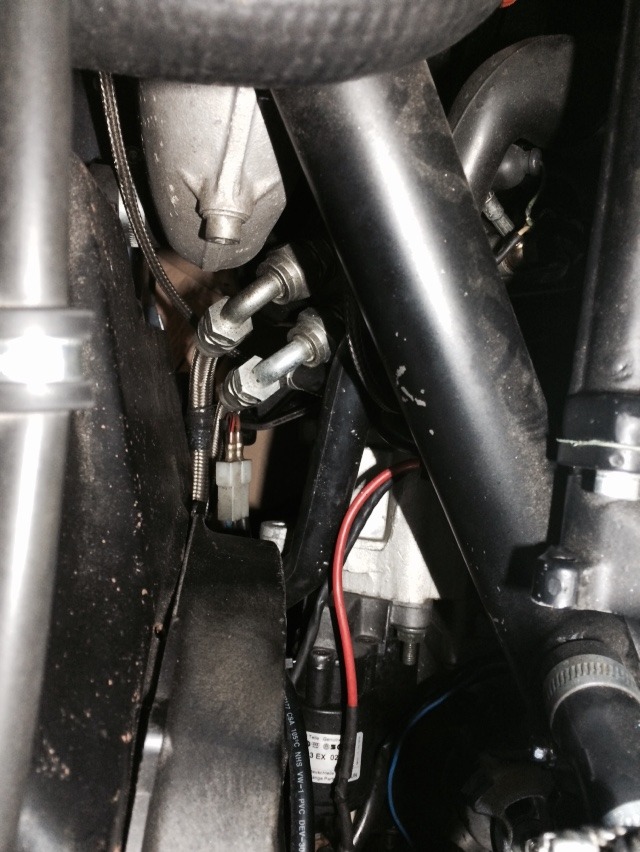

Charger side from underneath

Oil cooler pipes from above

And the washer bag. I'm keen to change the K&N filter out for the reasons you said, but it should still squeeze in and you can lift it out to refill it.

Hope this helps although it looks like you're running a custom integrated radiator/intercooler are you?

Posted

Old Timer

Ive swung my 180 degree charger outlet in towards the engine, pivoted around the central securing bolt if you get what I mean to give me more clearance to run a bigger core custom radiator. This means its going to be tight to connect up my charger outlet to the intercooler but im hopeful that one of these specialists is upto the job. My intercooler is also custom made and probably too large for what I need but ill be using it for now. I really didn't want the headache of having to connect everything up as without having a large stock of silicone and metal piping its going to be a nightmare to get it right first time and ill probably waste a lot of time and money ordering hoses and pipes that don't fit quite right.

0 guests and 0 members have just viewed this: None.